Innovative insulation for powerful e-motors

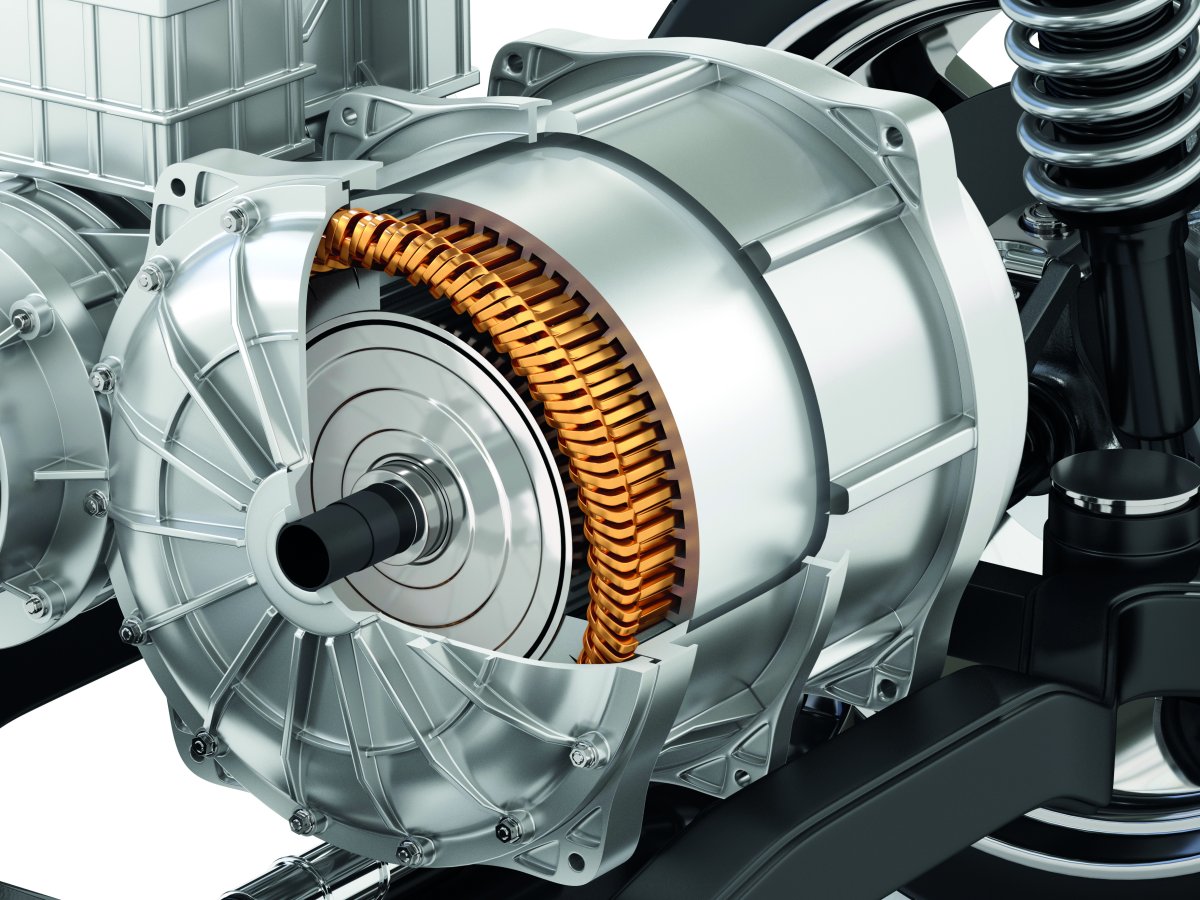

Powerful electric motors play a decisive role in E-mobility of the future. The latest generation of e-motors has higher voltages and thus a higher power density. This leads to increased waste heat due to mechanical friction and current-carrying conductors. Resulting in higher thermal loads for the components and materials. Conventional cooling methods such as air or water cooling reach their limits.

Thermal management based on direct contact cooling therefore is the future. The coolant flows directly through the engine and the heat is dissipated without diversions. This leads to an extension of the service life of all motor components, such as insulation, casting compounds, winding heads and magnets.

Established gear oils (automatic transmission fluids) are currently used as the coolant of choice. They offer good lubrication and electrical insulation with high thermal stability. Future developments will see them further optimised for direct cooling and marketed as so-called e-fluids. Special requirements are placed on the electrical insulaton, as specified by the IEC 63177 and T/CEEIA 415-2019 standards.

Composition

TRIVOLTHERM® E-Fluid-Safe is a three layer laminate.

Applications

TRIVOLTHERM® E-Fluid-Safe was specially developed for use in directly cooled electric motors. The main application are slot insulations, slot closures, stamped parts and intermediate insulations. It impresses with excellent media resistance and thermal behavior.

Krempel offers you TRIVOLTHERM® E-Fluid-Safe in rolls and sheets for individual further processing in your manufacturing process or as individual stamped parts. We are also able to produce custom-fit small tubes with a range of diameters for hair-pin winding technology.

International standards

They define requirements and test methods for insulation materials used in stators, rotors, windings and related components. The standards cover thermal endurance, mechanical strength, environmental resistance and electrical performance. Meeting these requirements is crucial for reliable insulation in demanding operating conditions.

TRIVOLTHERM® E-Fluid-Safe fully adheres to the guidelines specified in both standards, enhancing reliability and longevity of your e-motor components.

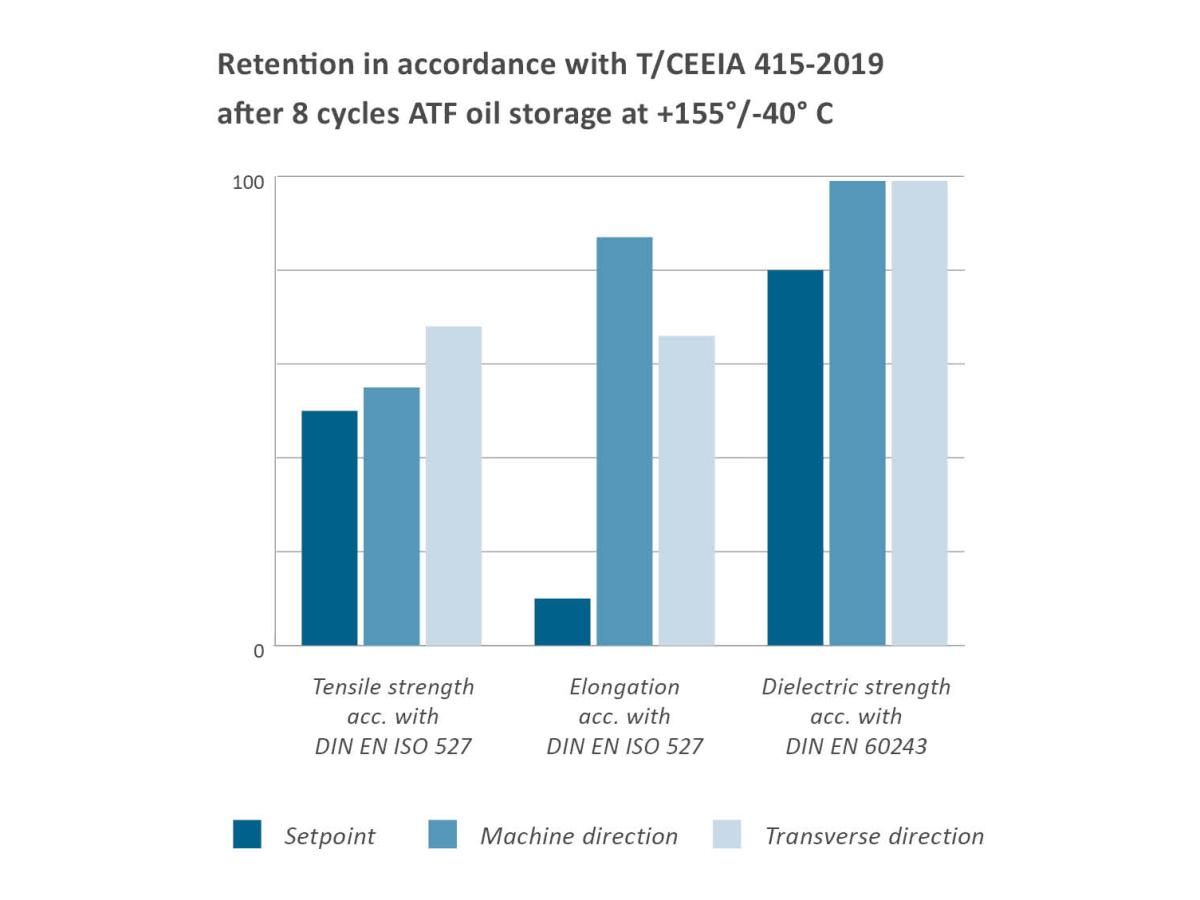

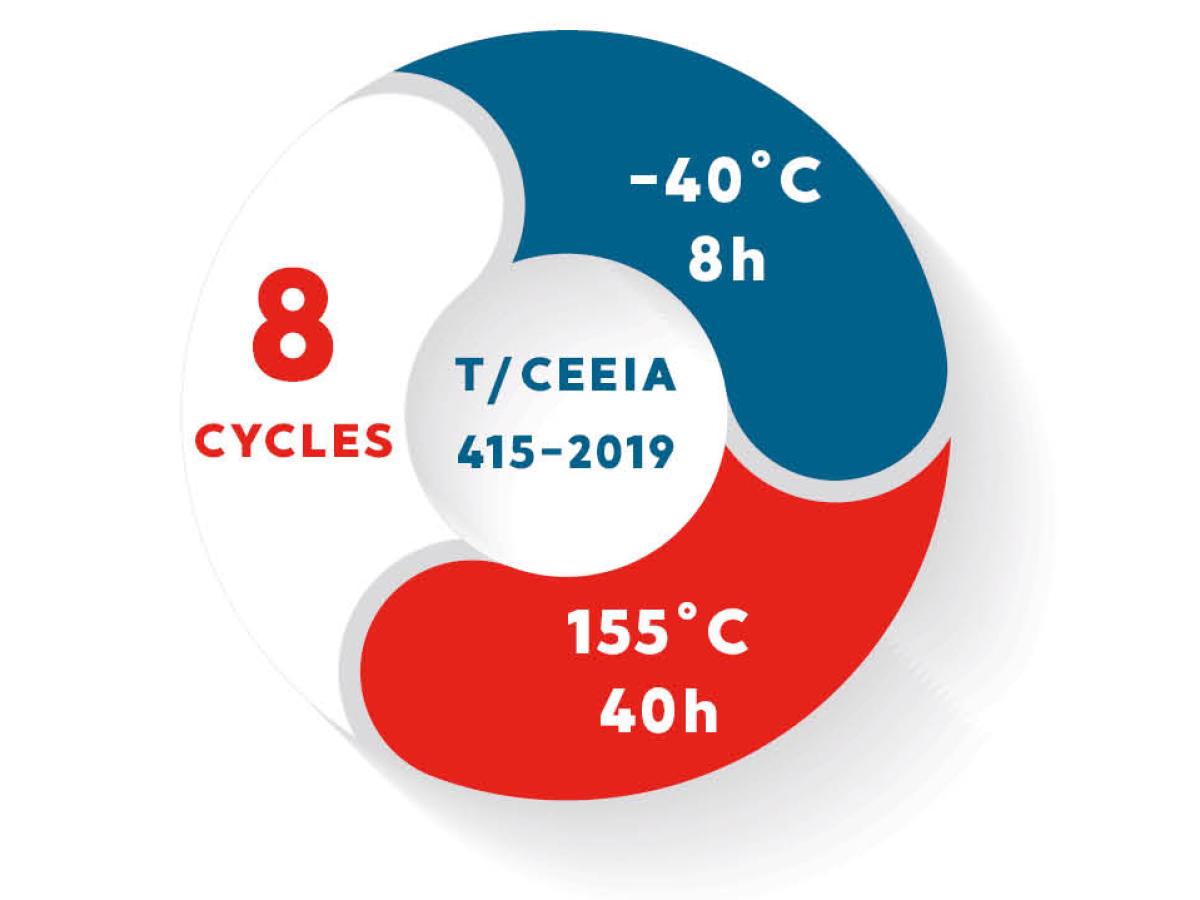

Test prodedure according with T/CEEIA 415-2019

The material undergoes cyclic exposure to alternating temperatures of +155°C and -40°C within a hermetically sealed container, automatic transmission fluid (ATF) serving as the surrounding medium.

Following eight complete thermal cycles between high and low temperatures, the material exhibits superior retention beyond the required thresholds. It demonstrates the ability to endure the prescribed temperature ranges without experiencing any form of degradation or deterioration.

Crucial properties including tensile strength, elongation and dielectric strength exhibit exceptional levels of preservation.

Downloads

TRIVOLTHERM®-E-Fluid-Safe

Electrical insulation laminate for liquid cooled e-machines