Best solutions for individual customer requirements

Manufacturing technologies at a glance:

- Coating systems (up to 2 m wide)

- Presses (up to 1.5 x 3 m)

- Autoclaves (up to 2.5 x 10 m)

- Tempering ovens (up to 2.5 x 2.9 x 3.5 m)

- Secure bonding (TLA0023 standard)

- Water jet cutting

- 3, 4, 5 & 9-axis milling

- 5 Axis router

- Injection & compression moulding

- Resin infusion & resin transfer moulding

- Convolute & filament winding

- Laminating

With over 30 years of experience in the composites industry, specifically in the areas of prepregs, rigid sheets and 2D and 3D components with thermoset, thermoplastic or elastic matrix, we have a deep understanding of the use of these materials in the security and defence industry.

Our prepregs can be easily coated on our systems and then processed on multi-daylight presses into sheets or complex 2D/3D components, which are used in a wide range of ballistic and civil protection applications, among others.

Shatter protection applications based on all types of ballistic fibres in combination with traditional and innovative resins can be produced as sheets up to 1.5 x 3 m and up to 3.5 x 10 m in our autoclaves. Production takes place as flat sheets and as complex moulded 2D or 3D components.

Thanks to our comprehensive manufacturing expertise, we offer customised solutions that meet the individual requirements of our customers.

Areas of application for Krempel protection technology

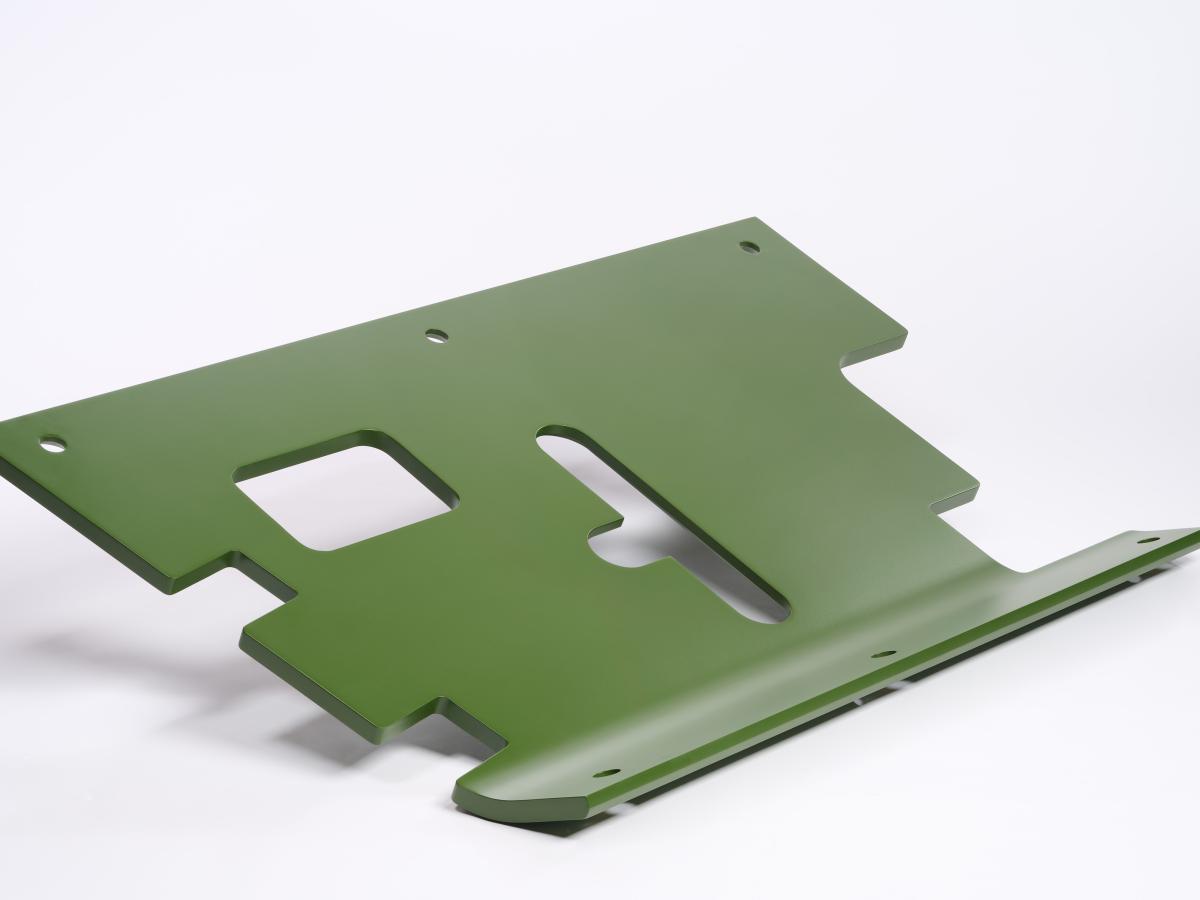

We produce high-quality ballistic protection components for wheeled and tracked vehicles. Using state-of-the-art materials and technologies, we offer flexible solutions that can withstand extreme conditions and are customised to our customers' needs. Our range includes semi-finished products (prepregs), sheets, blanks and 3D moulded parts made from materials such as

- E-glass roving with phenolic resin, modified epoxy resin or thermoplastic matrix

- S-Glass roving with modified epoxy resin

- Aramid fabric with rubber coating, PVB phenol or phenolic resin

- Customised multilayer laminates

Our composite materials also offer first-class protection for civilian and VIP vehicles as well as government and special protection vehicles. Thanks to our close cooperation with vehicle manufacturers, we have extensive expertise and use lightweight, high-performance materials. We supply semi-finished products, sheets, cut-to-size parts and 3D moulded parts made from materials such as

- Aramid fabric with rubber coating, PVB-phenol or thermoplastic

- UHMWPE fibres: Dyneema, Tensylon, Endumax

- Customised multilayer laminates

In the aviation sector, we successfully implement projects for ballistic protection elements both in civil aviation and for the defence industry. Krempel products offer maximum safety, robustness, weight optimisation and reliability and meet international standards such as those of the German Federal Aviation Authority (LBA).

Successfully realised projects that include Krempel protection technology:

- Ballistic-protected cockpit doors and partition walls

- Ballistic protection elements for Helicopters

- Radomes for antenna protection

Radomes and ballistic components protect civilian and military watercraft from salt water, extreme temperatures and mechanical and ballistic loads. Manufactured from glass fibre reinforced plastics, they undergo strict material selection, shaping and quality tests. Krempel supplies everything from a single source and serves the following areas:

- Radomes for antenna protection

- Sonar covers

- Ballistic protection for deck superstructures

Effective personal protection is essential in many security-relevant situations. Our products for protection against ballistic threats and stabbing weapons are subject to current official standards. Despite their high level of protection, these components offer maximum wearing comfort. This allows users to move flexibly and agilely. Many of the customised solutions are used in the following protective equipment:

- Bulletproof safety helmets

- Bulletproof and stab-proof protective waistcoats

- Protective shields for authorities and emergency services

In industrial environments, protective equipment is crucial to protect employees, especially in the event of flying parts and other hazards. Krempel products & materials offer effective protection here too and play their part in improving occupational safety.

Thanks to the use of high-quality materials and advanced construction methods, the devices are robust, durable and reliable. Krempel can look back on a number of successful projects:

- Splinter protection panelling in mechanical engineering, e.g. machine tools, high-pressure testing devices

- Impact and collision protection, bumpers

- Heat and thermal protection for hot presses

- Low temperature fibre composite applications

In safety-critical environments such as mobile field facilities, containers or government buildings, ballistic protection devices are essential. This ensures the safety of employees and also protects important facilities.

Krempel also offers products and materials with outstanding performance and reliability in this area. Thanks to a trusting co-operation with our suppliers and our own production facilities, we can offer a fair price-performance ratio. This enables us to manufacture protective elements such as spall liners made of rubberised pressed aramid fabric.

Ballistic tests

We set standards and attach great importance to the reliability and quality of our products. The ballistic tests carried out with our partners are at the heart of these endeavours and ensure that our products meet the highest standards.

Our certified tests and inspections follow the strict regulations of VPAM and Stanag. By precisely simulating real-life conditions, we test products such as vehicles, helmets, waistcoats, etc. for their performance under extreme ballistic loads. In doing so, we ensure that every component fulfils the highest requirements. Close cooperation with manufacturers of ballistic fibres also guarantees optimum use and reliable delivery capability.

Safe bonding of defence technology products

We are certified in accordance with the TL A-0023 standard of the Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support. This standard was developed to ensure the quality of adhesive bonding in the field of defence technology. It applies to the bonding of joined parts in the manufacture and repair of military products. It also specifies minimum requirements for quality assurance and describes the procedure for obtaining operational qualification.

Quality assurance & test procedures at Krempel Protection Technology

In terms of quality assurance, all areas of the company are certified in accordance with ISO 9001. In addition, certain areas and locations are also certified in accordance with EN 9100 and IATF 16949. In the area of ballistic composite materials, we carry out all the necessary tests, such as peel tests, tensile tests and 3-point bending tests, directly at Krempel. Thanks to our network and close cooperation with various testing and certification institutes, we can comprehensively fulfil individual customer requirements.