Composites and moulded parts for industrial applications

- Prepregs & UD Prepregs

- FRP & Rigid Laminates

- FRP Components

- Composite Tubes

- Pultrusion Profiles

Krempel has distinguished itself as a solution provider to many industrial fields, in addition to the medical, ballistic safety and mechanical and plant engineering sectors. In addition to fibre composites, which can be developed specifically according to customer requirements, we are also a competent partner in holistic project management, ranging from component design, material development and selection to prototype production and series production.

We have created a small selection out of a wide-ranging list of interesting projects, which are representative of industrial solutions.

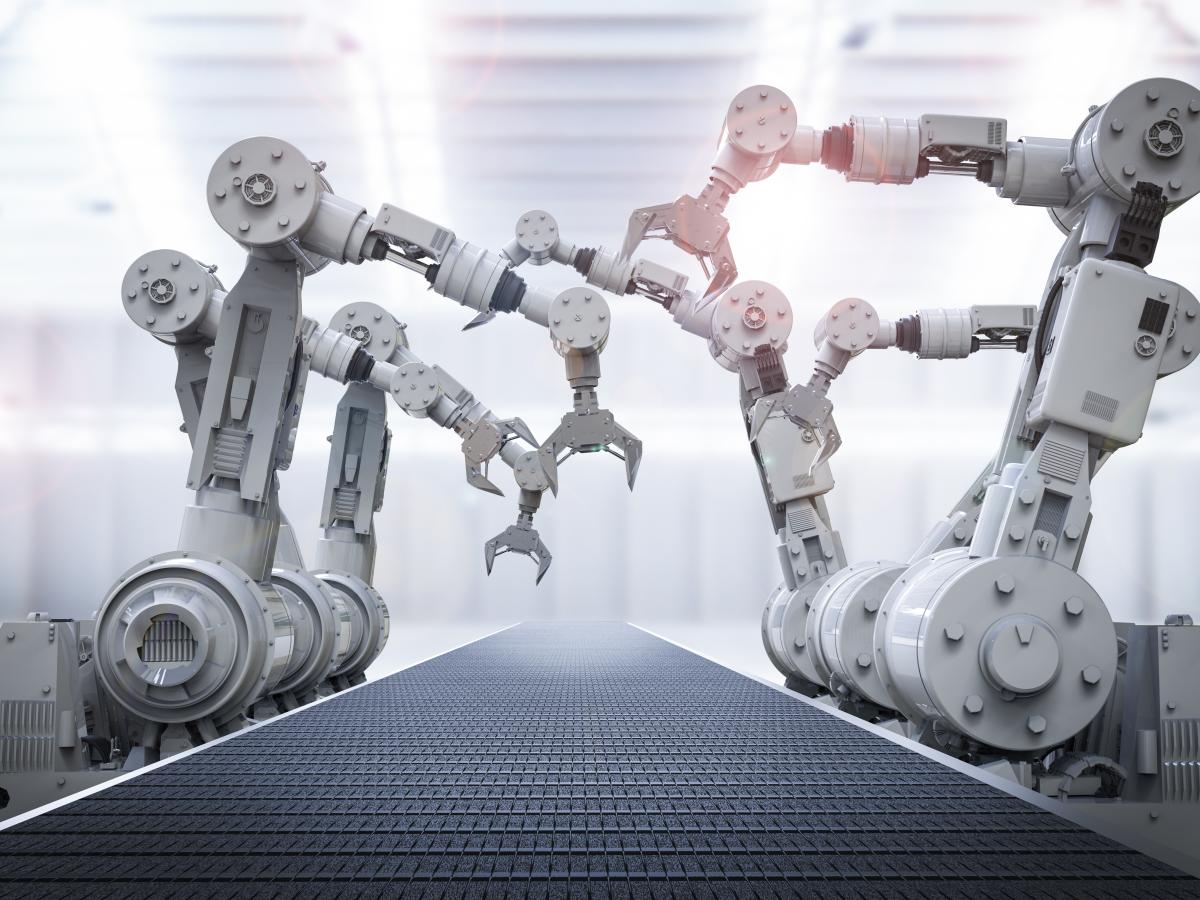

Robotics

Robot arms

One of our renowned clients uses carbon prepregs to manufacture robot arms. The robust and, above all, lightweight design offers many advantages in the field of series production.

Machinery & Plant Engineering

Heat resistant sheet components

Heat resistant sheets allow for thermal separation between the tool and the machine.

This has the following advantages:

- Reduced heating-up times for moulds and tools

- Optimised thermal processing

- Protection of plant parts (electronics, hydraulics etc.) increases their service life

- Uniform mould temperatures allow for controlled melt flow

- Significant energy savings (up to 40%)

Punching & printing technology

Punching strips and boards

CutGreen punching strips and punching boards are ideal for all types of punching and drilling processes where a stable base pad is needed.

In addition to our standard version, we also offer a special "Extra" variant for higher mechanical load capacity.

All CutGreen punching and drilling pads are made from 100% unbleached sulphate fibres and water, a truly natural product, which is therefore easy to recycle.

Machinery & Plant Engineering

Construction profiles

WACOSIT® profiles are playing an increasingly important role in mechanical engineering and plant engineering. Their strong mechanical and thermal properties make them ideal for industrial applications:

- Low weight

- High mechanical strength

- Low heat conductivity

- Chemical and corrosion resistance

- UV-resistance

Our customers from the paper machinery and dewatering systems, plant engineering and chemical plant construction sectors have had an appreciation for these properties for decades.

Conveying and screening technology

Springs

UD PREPREGS springs are used in the conveying and screening technologies. They are used in industries such as the food industry or the pharmaceutical industry. The high reliability, durability and corrosion resistance, as well as their fatigue resistance, make UD PREPREGS ideal for long-term use.

Motorsport & exclusive performance vehicles

Composite tooling and mould construction

Krempel manufactures lightweight yet robust components in series production for motorsport, for exclusive performance vehicles and vehicle finishing.

PREPREG materials with fibre composite materials are used to manufacture these. Both fibreglass fabric and carbon fibre fabric can be worked with as reinforcement materials.

The material has the following characteristics:

- High contour accuracy under process conditions

- High surface quality

- Long service life

- Chemical resistance

- Low thermal mass

- Coefficient of thermal expansion similar to that of the part to be manufactured

Sport & leisure

High performance materials for high performance athletes

For the sport of cycling, Krempel supplies carbon PREPREGS, which are used to construct light frames and durable spokes. The PREPREGS, which were individually adapted to customer requirements, were used to produce components that conform to drawings.