The generation of energy from wind power is one of the central pillars of the move from nuclear and fossil energy sources to renewable and regenerative energy. Krempel is actively helping to shape this move, because wherever there are wind turbines, whether onshore or offshore, there’s a high chance that they’re using Krempel materials. We have been a leading partner to all renowned wind turbine manufacturers for over 20 years, and have been actively involved in crucial developments; indeed, it was our solutions that rendered these developments possible in the first place. As part of this process, we work in very close collaboration with the development teams of system and component manufacturers, and help design technical solutions for the particular challenges faced in the wind energy technology sector.

Our solutions for wind energy technology

We provide insulation materials, components and other materials for:

- High-voltage generators

- Gearless generators

- Low-voltage motors of all sizes (e.g. for pitch and azimuth motors)

- Transformers

- Rotor blades

Krempel materials literally make light work of the demanding challenges faced by wind turbine components. Our composite materials, for example, have the perfect properties for use in wind energy applications: they are lightweight yet highly resilient and flexible at the same time. As well as composite materials, we also offer an entire range of other materials and components.

Our product portfolio for wind turbines

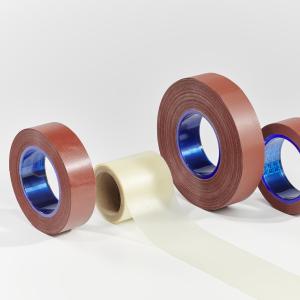

- Electrical insulation for VPI, resin rich and low-voltage applications, e.g. mica materials and multi-layer laminates, provided as narrow tape, punched parts or moulded parts

- Conductive tapes based on PET non-woven fabric and glass fabric

- Rotor banding tapes made from glass, carbon and aramid fibres up to class H

- Prepregs based on non-woven and woven fabrics, unidirectional, also available with epoxy resin binding agent

- Insulating tubes, woven tapes, cords

- Slot wedges made from pultruded profiles and mechanically processed from sheets, also magnetic and with swell mats included

- Filament winding tubes for maximum force absorption and energy transmission

- Glass-fibre and carbon-fibre-reinforced plastic profiles based on epoxy, polyester and vinyl resins

- Three-dimensional moulded parts made from fibre-reinforced plastics

Generators

High-voltage generators

- Electrical insulation for VPI and resin rich

- Mica materials for main insulation

- Multi-layer laminates for use as slot boxes

- Conductive tapes based on PET non-woven fabric and glass fabric

- Rotor banding tapes made from glass, carbon and aramid fibres up to class H

- Prepregs based on non-woven and woven fabrics, unidirectional

- Insulating tubes, woven tapes, cords, also available with resin impregnation

- Slot wedges made from pultruded profiles and mechanically processed from sheets, also magnetic and with swell mats included

Generators

Gearless generators

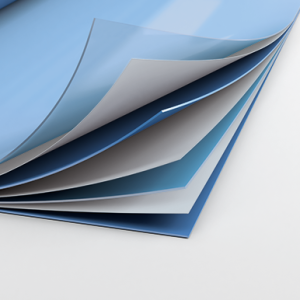

- Electrical main insulation: Multi-layer laminates made from aramid papers, PET films, PI films and mica materials, also available as slot boxes, stamped parts, moulded parts, pre-assembled and as a KIT

- Prepregs based on non-woven and woven fabrics, unidirectional

- Insulating tubes, woven tapes, cords, also available with resin impregnation

- Slot wedges made from pultruded profiles and mechanically processed from sheets, also magnetic and with swell mats included

- Three-dimensional moulded parts made from fibre-reinforced plastics

Connecting tubes

- Filament winding tubes for maximum force absorption and energy transmission

Rotor blades

- Prepregs based on non-woven and woven fabrics, unidirectional, also available with epoxy resin binding agent and cured

- Woven tapes, cords

- Multi-layer laminates for electrical insulation

- Pultruded plastic profiles, glass-fibre and carbon-fibre-reinforced, based on epoxy, polyester and vinyl resins

- Three-dimensional moulded parts made from fibre-reinforced plastics

Materials for wind turbines from Krempel

You can have confidence in this:

- Extended service life

- High temperature resistance

- Cost efficiency

- Low weight

- High functional reliability

- Highly robust and powerful