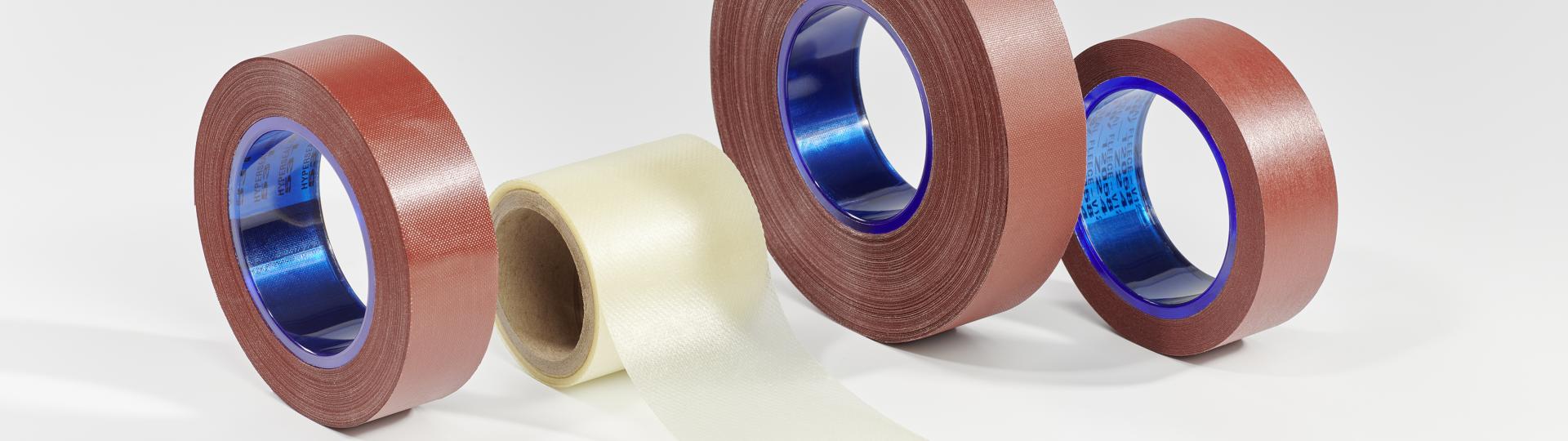

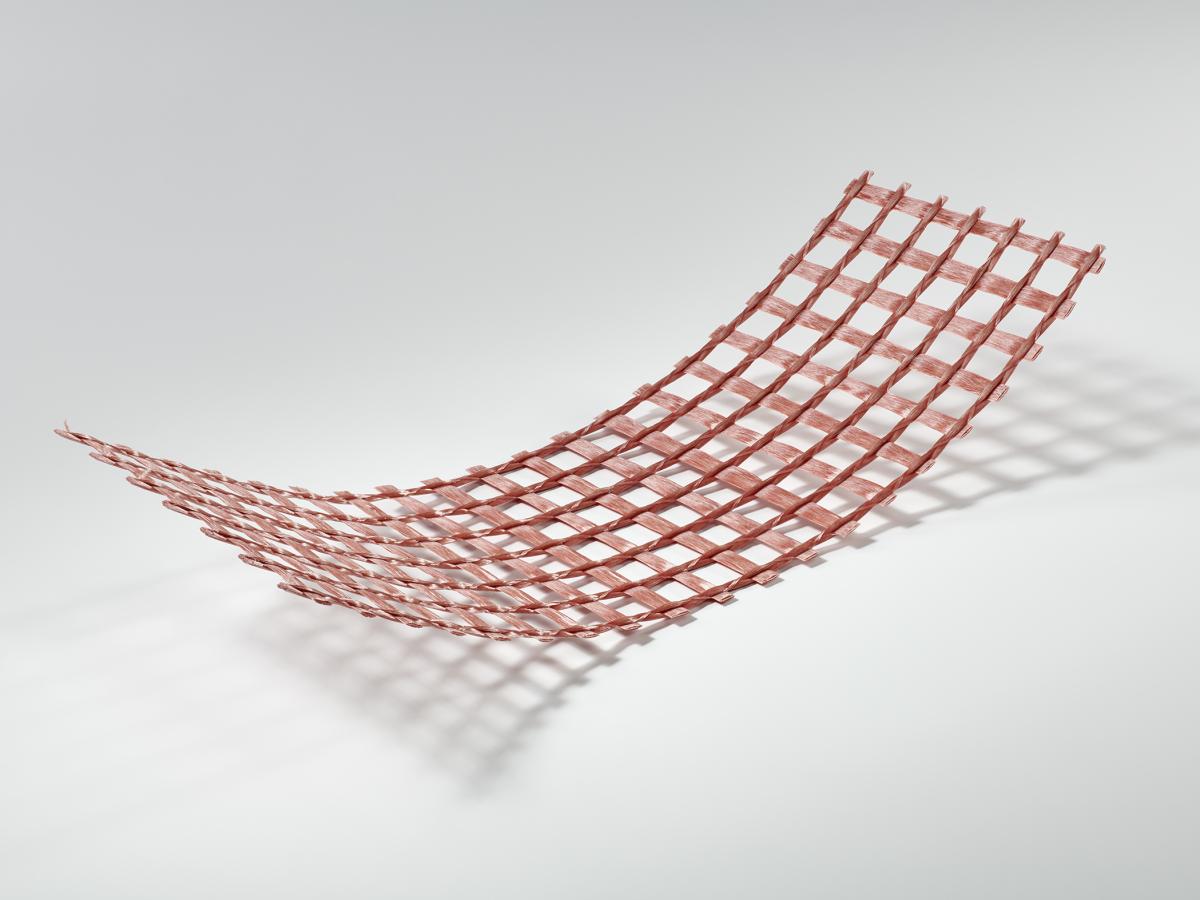

With this type of flexible insulation, different types of single-layer substrate materials are given a cured resin impregnation or resin coating. The materials that we process as substrate materials are polyester woven and non-woven fabrics, glass fabric and glass roving mesh fabric. The impregnation is performed using acrylic resin or epoxy resin. The special expertise lies in the resin formulas and in the production process; the interplay between the two is something that we have perfected over the decades.

The impregnation of the substrate materials with synthetic resin and the subsequent curing process leads to increased electrical strength and a high level of rigidity with a low material thickness. These improved characteristics make it possible to solve demanding construction tasks in generator, transformer and motor construction.

For certain applications, the single-layer surface insulation materials also feature an epoxy resin adhesive layer on one or both sides to allow for powerful and thermostable adhesive connections. This adhesive layer is dry and is still in the reactive B-stage. When exposed to temperature and pressure, the adhesive melts and then changes to the cured, stable C-stage.

The choice of flexible insulation materials (with cured resin impregnation or resin coating) depends on the required properties. Every material combination is characterised by specific values. We combine these in line with the demands of your application.

Applications of for flexible insulation materials with cured resins

- Strand insulation

- Winding insulation (for turbo generators with direct conductor cooling)

- Layer insulation (and reinforcement of dry-type transformers)

- Spacers / crack stop in casting (mesh fabric)

- Pole insulation

- Automatic circuit breakers with spark quenching chamber