We generally take an uninterrupted power supply for granted. Very few of us are aware of the technology behind it, technology such as that offered by Krempel – insulation systems for liquid-filled power and distribution transformers.

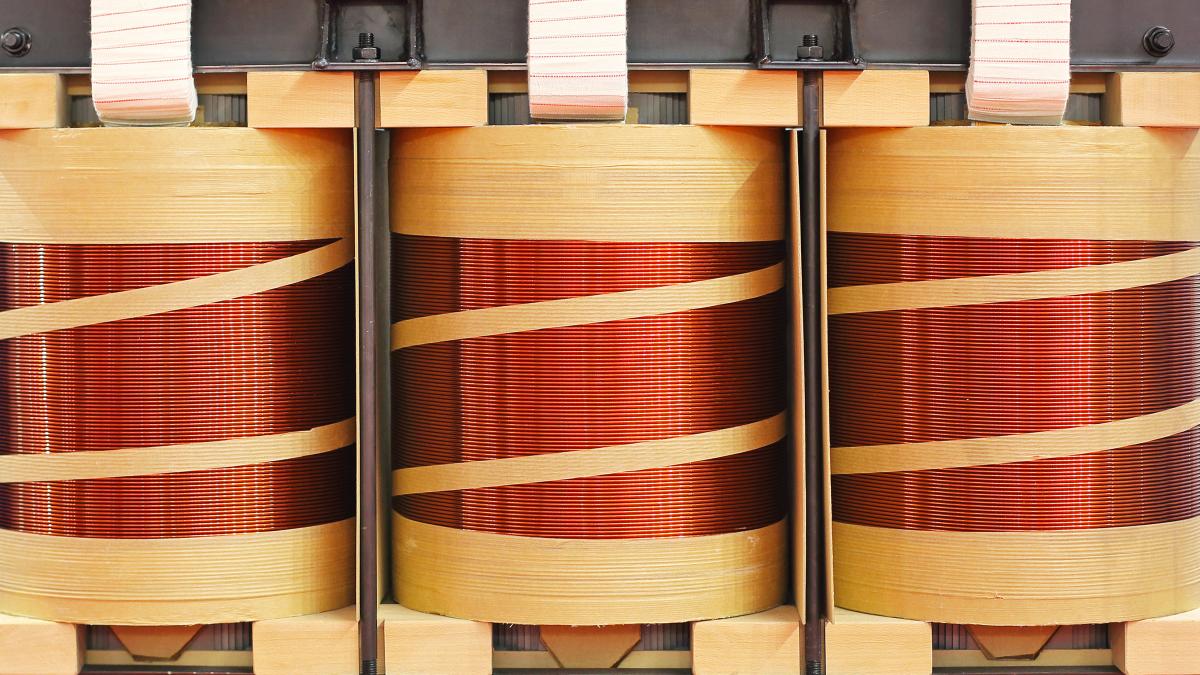

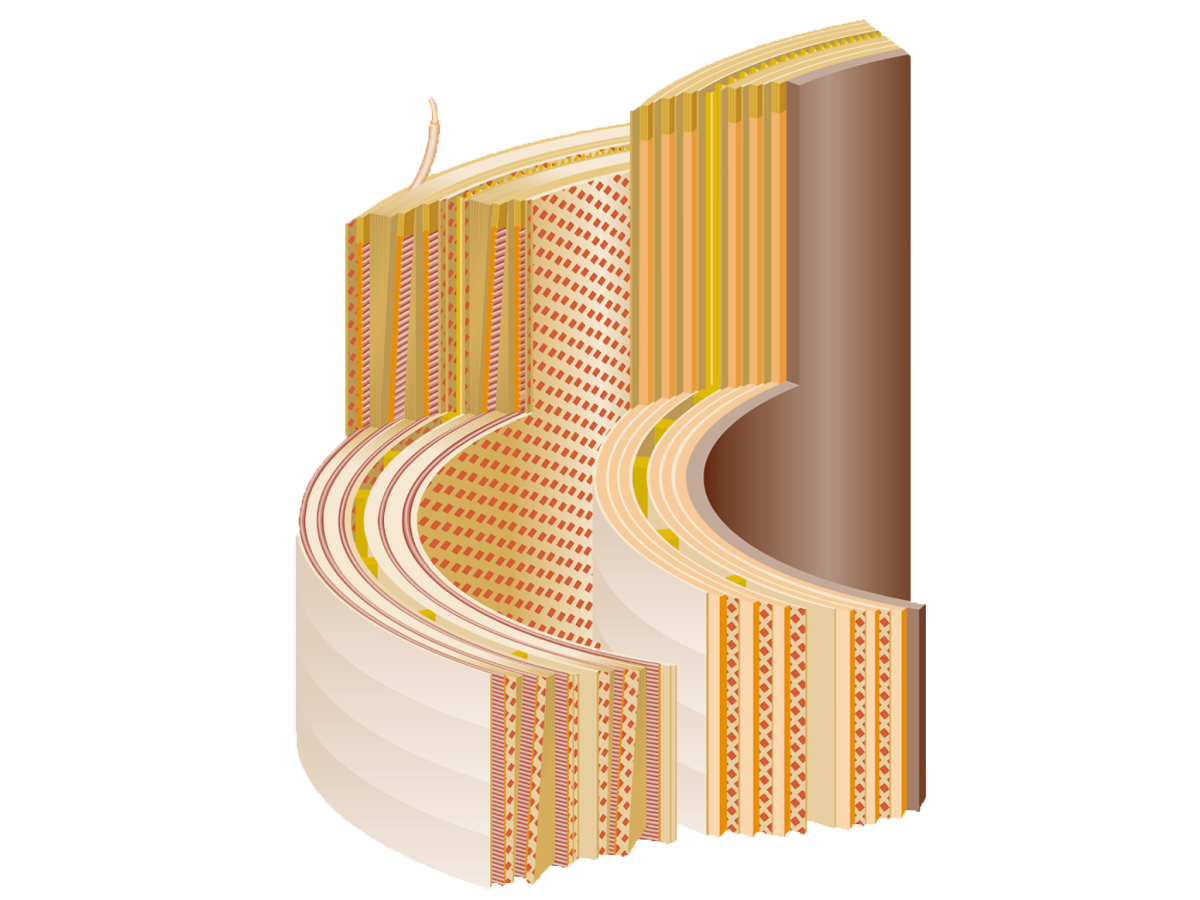

The unrestricted function of liquid-filled transformers over many years is largely determined by the quality of the insulation materials used. They influence the optimum distribution of liquids such as oil and ester in the transformer. During the production of transformers, but in particular during subsequent operations, insulation materials must withstand many different mechanical, thermal, electrical, chemical and climatic strains – with Krempel insulation materials, this comes with a lasting guarantee.

Our solutions for liquid-filled transformers

- Presspaper for layer insulation

- Pressboards, corrugated board, ladder grid and ladder duct for insulating cylinders and cooling channels

- PREPREGS for external bandings

- Crepe paper tubes for insulating circuit connections

The most important insulation materials when manufacturing liquid-filled transformers are presspaper and pressboards and machined parts made from pressboard. We are one of the world’s leading manufacturers in this field, with a history spanning more than 100 years.

Our pressboards have very special qualities, depending on the cellulose type, fibre structure and production process.

From standard to innovation

In addition to standardised electrical insulation materials of proven premium quality, our innovative and individual solutions allow us to stand out. These are the result of close interaction with our customers. Not only do we make improvements to established insulation materials, we also have the tools and expertise gleaned from countless projects to bring genuine, radical innovations to the market. Our thermally upgraded paper for high-temperature applications up to 140°C is a recent testament to our innovative power. It is one of a kind on the global market. It opens up completely new possibilities for transformer construction.

Innovative insulation materials for renewable, environmentally friendly energy solutions

Krempel offers innovative insulation materials which meet the requirements of green energy solutions:

- Increased overload capacity

- Designs with peak loads

- High temperature resistance

- Extended service life

- Environmental sustainability

- Compact and light design

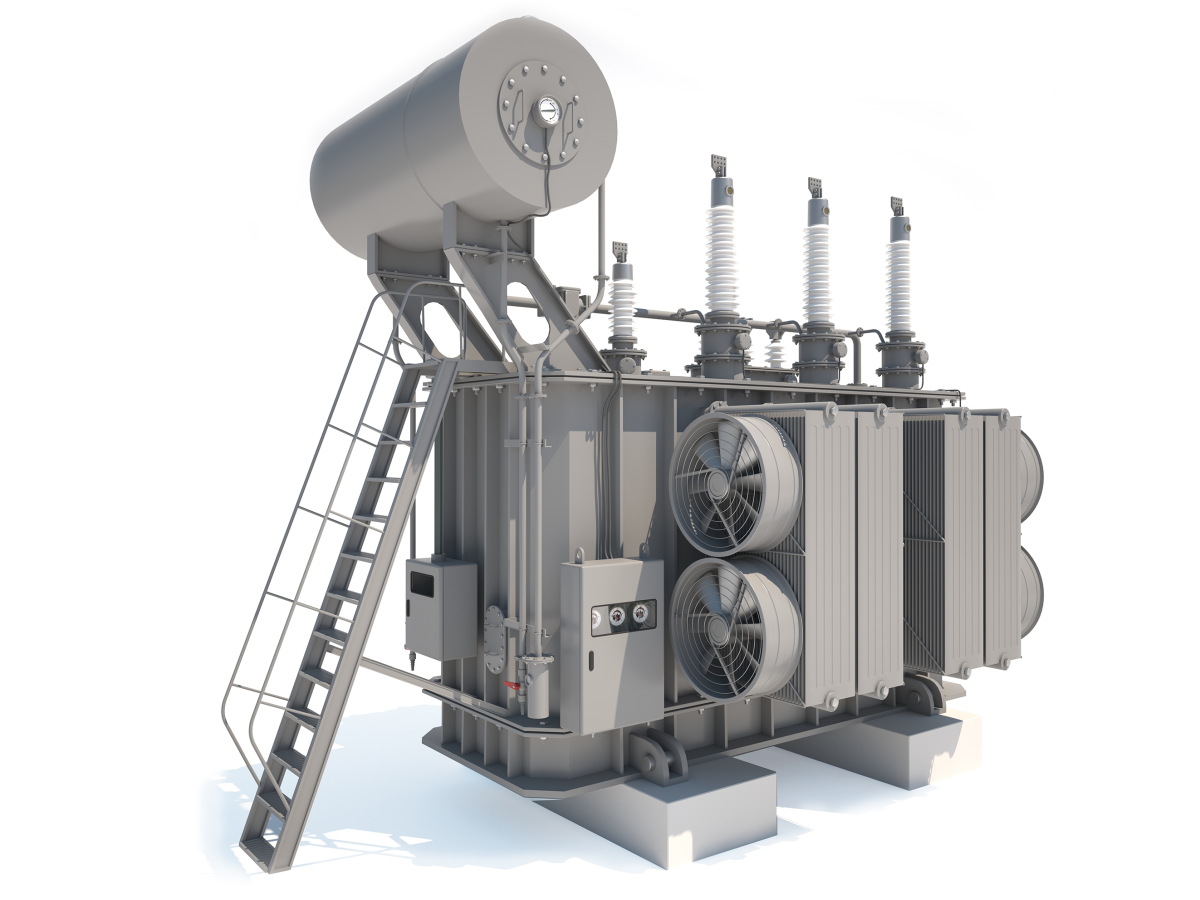

POWER TRANSFORMERS

Power transformers are of key importance in our electricity networks. Reliable, durable insulation in the transformer is essential for power networks to function smoothly. Our core bandings for power transformers are ideal for this. Our electrical insulation materials, especially pressboard, are also particularly suitable for insulating cylinders, mouldings, spacers, spacer washers, pressure rings and conductor supports. We offer both individual parts and complete systems in cooperation with long-standing partners.

DISTRIBUTION TRANSFORMERS

Distribution transformers are key to transporting electricity to consumers. Krempel’s insulation materials fulfil an important role in ensuring that the power supply to consumers is secured every day. Krempel offers perfectly matched materials for all thermal classes: 105°C - 120°C - 130/140°C - 180°C.

Depending on the desired thermal class, the following base materials can be used:

- Pure cellulose papers (105°C)

- Thermally upgraded cellulose papers (120°C)

- Cellulose papers reinforced with aramid (130/140°C)

- Pure aramid papers (180°C)

Our portfolio of distribution transformers:

- Presspaper (PSP 3055) and presspaper with partial epoxy resin coating (DPP) for layer insulation

- Pressboards, corrugated boards, ladder grids and ladder ducts for insulating cylinders and cooling channels

- Prepregs for external bandings

- Crepe paper tubes to insulate switch connections

Layer Insulation

- Presspaper(PSP 3055, Typ P.2.1A)

- Presspaper with lower density (PSP 3055 SL, Typ P.4.1A)

- Presspaper partially coated with B-stage epoxy resin (Krempel-DPP)

Insulating Cylinders

- Presspaper (PSP 3050, Typ B.2.1B; PSP 3051, Typ B.4.1)

- Pressboard, strips, spacers (POWERBOARD AK, Typ B.3.1A)

Outer Bandings

- Thread-reinforced polyester non-woven impregnated with B-stage epoxy resin (PREPREG EFBD)

Insulation for coil connections

- Crepe paper tubes

Spacer for cooling ducts

- Corrugated chipboard

- Slatted carpets

- Mouldings

SPECIAL TRANSFORMERS

Krempel’s wide range of insulation materials also includes system solutions for traction transformers, instrument transformers, reactors, capacitors and other special transformers. These insulation materials include:

- Special insulation papers

- Multi-layer insulation materials

- Conductive non-woven materials and technical textiles