Transformer Assembly Kits Engineered for Efficiency

Krempel specializes in delivering complete insulation component packages for both power and distribution oil-immersed transformers. Our package concept ensures that OEMs receive all necessary parts - when and how they’re needed.

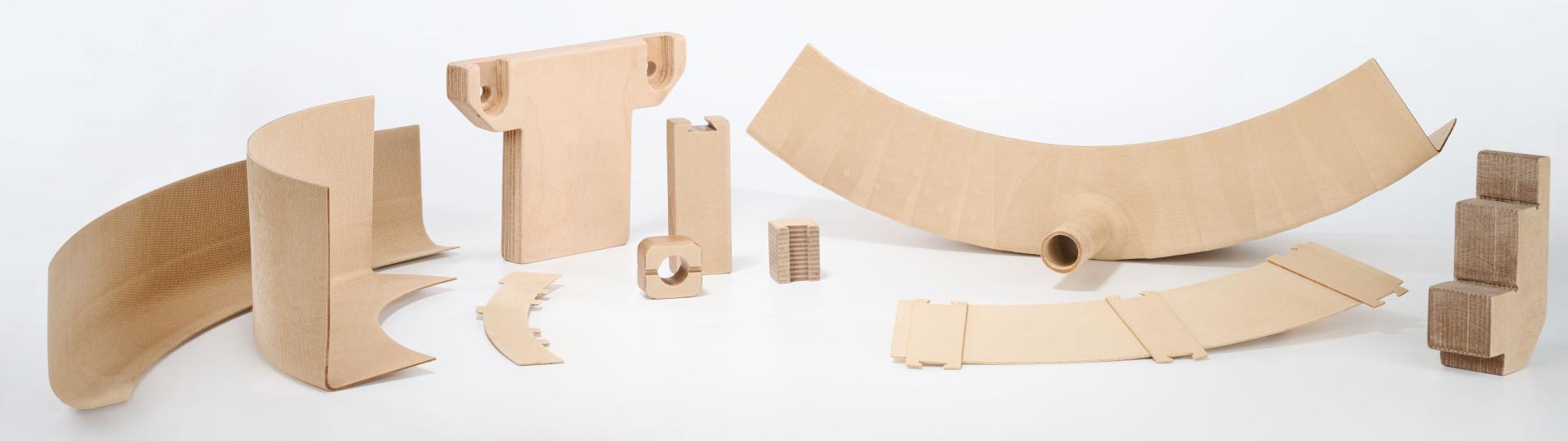

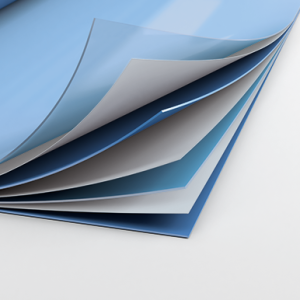

Our insulation components, crafted from premium cellulose-based pressboard, are engineered to meet the stringent demands of modern electrical equipment. Manufactured exclusively from the highest purity pressboard, these components are known for their exceptional cleanliness, mechanical strength, and reliability. The material’s superior ply-bond adhesion contributes significantly to the structural integrity and long-term durability of our product range.

We provide a comprehensive portfolio of solid insulation components tailored for power and distribution transformers. Customers can select from a wide array of standard parts or opt for custom-engineered solutions designed to meet unique application requirements. Our manufacturing capabilities cover both dry and wet sheet processes, and we also supply preassembled winding packages. Krempel proudly holds ISO 9001 certification, affirming our commitment to quality.

These components serve as essential barriers in the oil-cellulose insulation systems of transformers. Their adaptability allows precise alignment with specific electrical field patterns, enabling optimal insulation design. This contributes to more compact transformer construction and reduced material usage - yielding both technical and economic benefits.

Your Benefits at a Glance:

- Single-source supply for full insulation kits

- Delivery aligned with production timelines

- Custom pricing by scale weight or net calculated weight

- Efficient logistics and inventory planning

Winding Components

Winding components are part of the transformer's internal insulation system and are placed directly in the winding areas. Their function is to provide structural support, maintain safe dielectric distances, and allow the circulation of insulating oil between the winding layers.

They are primarily used within the windings of power and distribution transformers, both single-phase and three-phase, in areas where insulation between layers, electric field control, and structural support for the winding are required

- Cylinders with strip assemblies

Reinforced insulating cylinders equipped with dielectric strips for radial separation; their primary function is to serve as structural support for the winding assembly. - Radial spacers

Thin insulating elements positioned between winding layers to ensure uniform spacing and facilitate thermal dissipation. - ID/OD collars

Rings placed on the inner or outer diameter of the winding for mechanical fixation and electrical control. - Segments

Modular components utilized for the assembly of customized rings or structural configurations. - Molded parts

Components with complex geometry, fabricated to customer specifications, primarily designed to insulate the outermost layers of the winding and mitigate partial discharge occurrences. - Shielding rings

Custom-engineered components designed to ensure uniform electric field distribution and prevent local field intensifications within the insulation system.

Sizing Elements

Components used to precisely adjust the relative positions of the transformer’s internal parts, ensuring both electrical insulation and mechanical stability. They help maintain critical distances between windings, core, and support structure. Sizing elements are used in power and distribution transformers to ensure a stable structural configuration, reinforce the insulation between components and enable efficient cooling by oil circulation

- Barriers and formed head sheets

Molded plates that provide axial insulation between windings or between windings and the core, preventing partial discharges - Radial strips

Insulating sheets arranged between winding layers to ensure uniform separation and oil flow channels. - Column support spacers

Elements that provide vertical mechanical support within the core structure and windings. - Laminated rings

Composite rings used to reinforce insulation between windings or between windings and tank, also for electric field control.

Core Support Structures

Parts designed to fix the transformer core inside the tank and support the mechanical loads transmitted by the winding. Their design must consider thermal expansion and electromagnetic forces acting during operation. They are used at the bottom of the core-coil assembly to ensure core alignment, distribute coil weight and prevent internal movement, particularly in transformers with high levels of vibration or thermal movement.

- Stepped blocks for core fixation

Stackable or multi-level parts that stabilize and centre the core - Coil support blocks

Rigid supports placed under the windings to keep them in position during operation or transport.

Beam and Lead Support

Components that provide structural support to the internal transformer beams and guide the conductor outlets from the windings. They are designed to resist mechanical forces and maintain insulation integrity. Beam and Lead Support parts are used at the top of the coil assembly, where conductors are connected to the external system of the transformer. They are also key in transformers with high current or high voltage connections.

- Laminated beams

Composite or reinforced beams used to support winding parts or assemblies inside the transformer. - Lead exit support structures

Parts that fix and protect the output cables, ensuring safe dielectric paths to the external terminals.

Custom parts

We manufacture special components designed under specific customer requirements. These parts fulfil unique functions in electrical or structural assembly, in situations where standard solutions are not feasible. They are applied in special transformers, custom designs, high voltage solutions or projects with specific geometrical restrictions and quoted individually according to geometry and complexity of the manufacturing process.

Product types:

- Molded parts

- Custom shielding rings

- Structural components with non-standard geometry

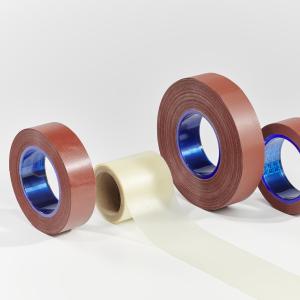

Flexible Kit Solutions to Support Your In-House Production

Our Insulation Kits are designed to complement the in-house production of transformer manufacturers who manufacture some components on their own but need external support to complete their assemblies. These kits include modular sets of pre-assembled or individual parts, tailored exactly to your technical specifications.

Krempel Insulation Kits are used in power or distribution transformer assembly plants, especially on lines where time optimization, reduction of assembly errors and ensuring uniformity between units are sought. They are also ideal for projects with high design variability or short production cycles.

- Pre-assembled cylinder and strip groups:

Subassemblies ready to be installed in the winding area. - Static rings:

Acts as a fuse and cut the circuit in case of overloads or short circuits. - Support blocks:

Structural elements supporting the core or coils. - Molded parts:

Complex components adapted to specific areas of the design. - Custom elements:

Customized parts developed according to customer's drawings or unique requirements