Depending on the type of cellulose, fibre preparation and machine settings, Krempel offers various types of presspaper and pressboard with very special qualities. These cellulose products are manufactured on special paper machines; we have one of the world's largest production facilities for continuously manufacturing presspaper as well as state-of-the-art presses for the production of pressboard. The composition and properties of presspaper and pressboard for electrical insulation are standardised according to IEC 60641. However, we also manufacture customized special types.

PRESSBOARD

During the production of pressboard, the wet paper web is wound onto the so-called format roller in several layers and then couched. Once the required number of layers or thickness has been reached, the "wrap" is cut. The resulting raw pressboard is automatically transported into a high-performance press, which ensures good wet densification and dewatering. Depending on the type of pressboard, it is either dried in a multi-level heating press under pressure (POWERBOARD AK type) or using pressureless drying with subsequent calendering (types PSP 3050, PSP 3051).

Our portfolio of pressboards:

| Type |

IEC designation |

Description |

|---|---|---|

| POWERBOARD AK | Typ B.3.1A IEC 60641-3-1 |

Hot-pressed, dimensionally-stable pressboard, natural colour |

| POWERBOARD AK CG / PHG | Typ LB.3.1 A IEC 60763-3-1 |

Laminated pressboar made from Powerboard AK |

| PSP 3050 | Typ B.2.1B IEC 60641-3-1 |

High-density, calendered pressboard, natural colour |

| PSP 3051 | Typ B.4.1 IEC 60641-3-1 |

Mouldable calendered pressboard, natural colour |

| PSP 3010 | Typ B.6.1A IEC 60641-3-1 |

High-density, calendered pressboard, orange-brown |

Available dimensions for pressboard:

|

Thickness pressboard: |

0,8 - 8,0 mm |

|

Thickness laminated pressboard: |

9,0 - 120 mm |

| Format POWERBOARD AK: | 2.200 x 4.200 mm |

|

Format of calendered pressboard: |

1.000 x 2.000 mm |

Other formats and individual solutions on request.

PRESSPAPER

In the production of presspaper, the prepared cellulose fibres are placed on several circular screens (screen cylinders) arranged one behind the other on our paper machines and the wet paper web is couched to form the wet, multi-layer presspaper. Following this sheet formation process, the fibre structure is mechanically dewatered, dried and smoothed and compacted between the rollers of our supercalenders. This gives the presspaper its required thickness and density and thus its good mechanical and electrical properties.

Our portfolio of presspaper and DPP:

| Type | IEC designation |

Description |

|---|---|---|

| PSP 3055 | Typ P.2.1A IEC 60641-3-2 |

High density calendered presspaper with high chemical purity, natural colour |

| PSP 3055 SL | Typ P.4.1A IEC 60641-3-2 |

Low density calendered presspaper with high chemical purity, natural colour |

| Nomex®910 | - |

High-temperature resistant presspaper reinforced with Nomex® aramid fibres |

| KREMPEL-DPP | - |

3055 SL presspaper or Nomex®910 with partial resin coating in the B-state |

| PSP 3040 | Typ P.6.1B IEC 60641-3-2 |

Calendered presspaper for dry applications, grey-black |

Available dimensions for presspaper:

| Thickness pressboard: | 0,075 - 1,0 mm |

|

Thickness DPP: |

0,05 - 1,0 mm |

| Parent roll width: | max. 2.100 mm |

| Cut narrow rolls: | ≥ 6,0 mm |

Other format products and individual solutions on request.

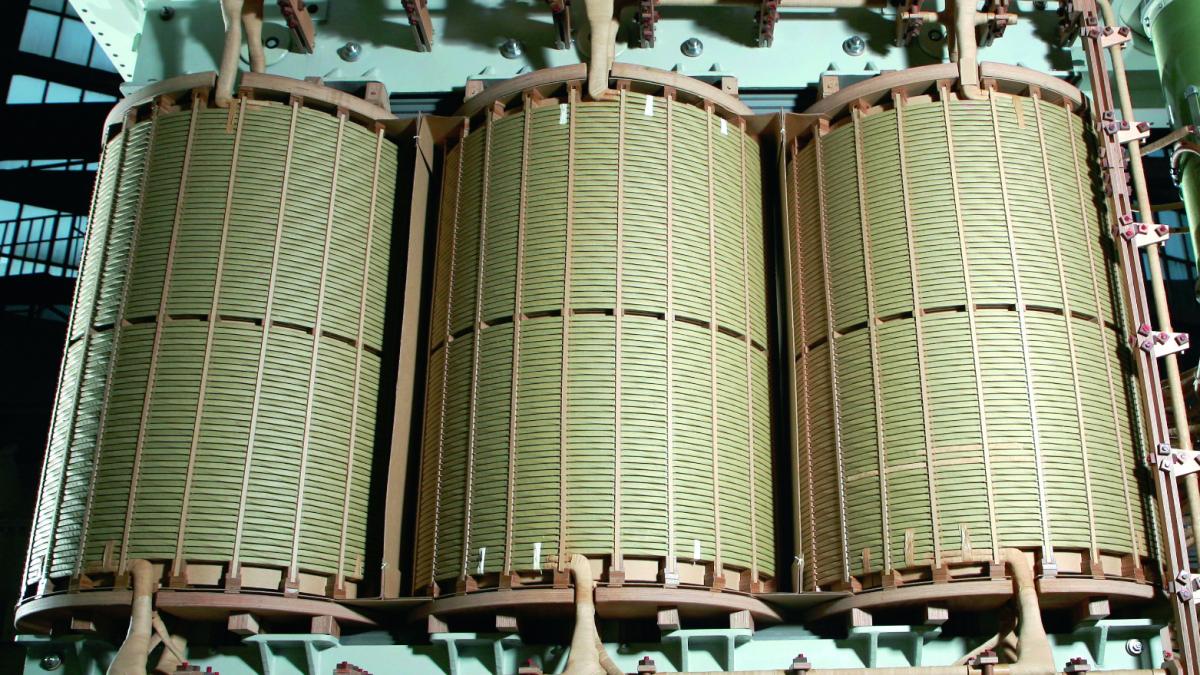

Applications for pressboard

- Layer insulation, core insulation, winding insulation

- Insulation cylinders

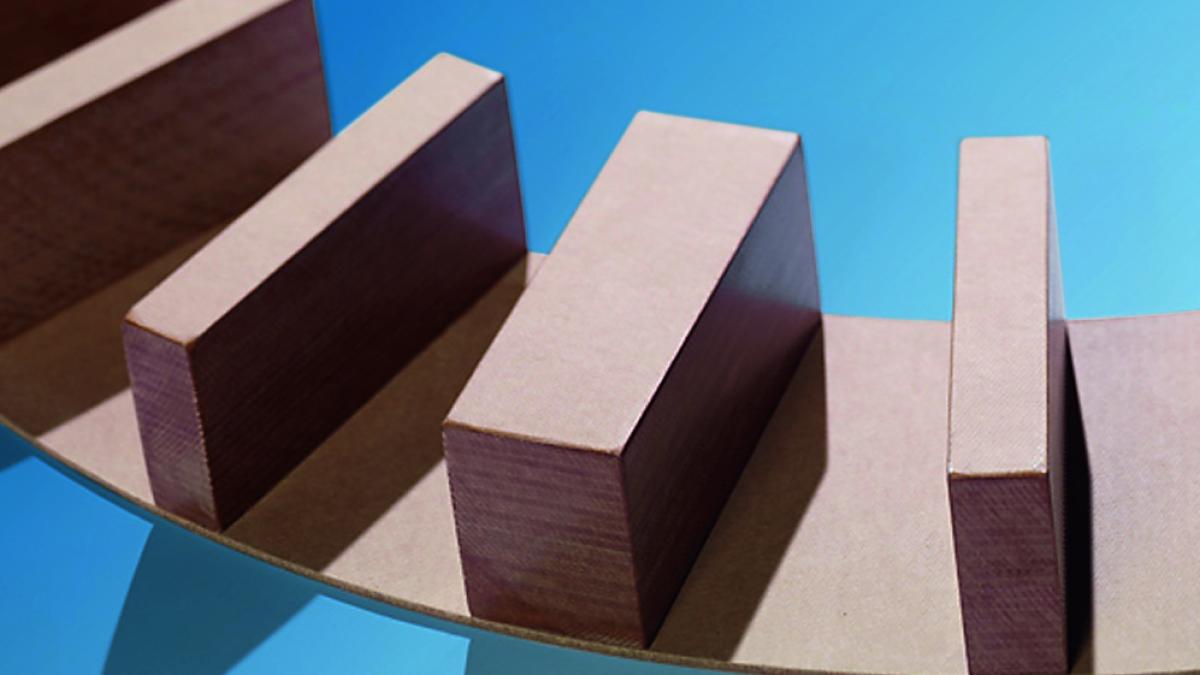

- Mouldings, bars and cooling channels

- Spacers and washers

- Printing plates, printing and shielding rings

- Dielectrics in capacitors

- Punched and folded parts

For applications in liquid-filled transformers we produce a wide variety of presspaper and pressboards, which are also process into presspaper with diamond-dotted resin coating (DPP), corrugated board, laminated pressboard, ladder ducts and ladder grids.

- All-round insulation, intermediate insulation

- Groove linings

- Stator and rotor end discs

- Coilformers

- Punched and moulded parts

For the insulation of motors, coils and other electrical devices where the presspapers and pressboards are not impregnated with a liquid dielectric, we produce a wide range of different types of presspaper and pressboard, some of which have tailor-made properties for special applications.

CutGreen punching strips and punching boards are ideal for all types of punching and drilling processes where a stable base pad is needed.

In addition to our standard version, we also offer a special "Extra" variant for higher mechanical load capacity.

All CutGreen punching and drilling pads are made from 100% unbleached sulphate fibres and water, a truly natural product, which is therefore easy to recycle.

- Support material for printing processes

- Packaging

- Shoe manufacturing

- Sanding paper

- Conveyor belts for electronic components

Not only are our presspaper and pressboards ideal as an insulation material, but also for many different uses.