Versatile material options with excellent processing qualities

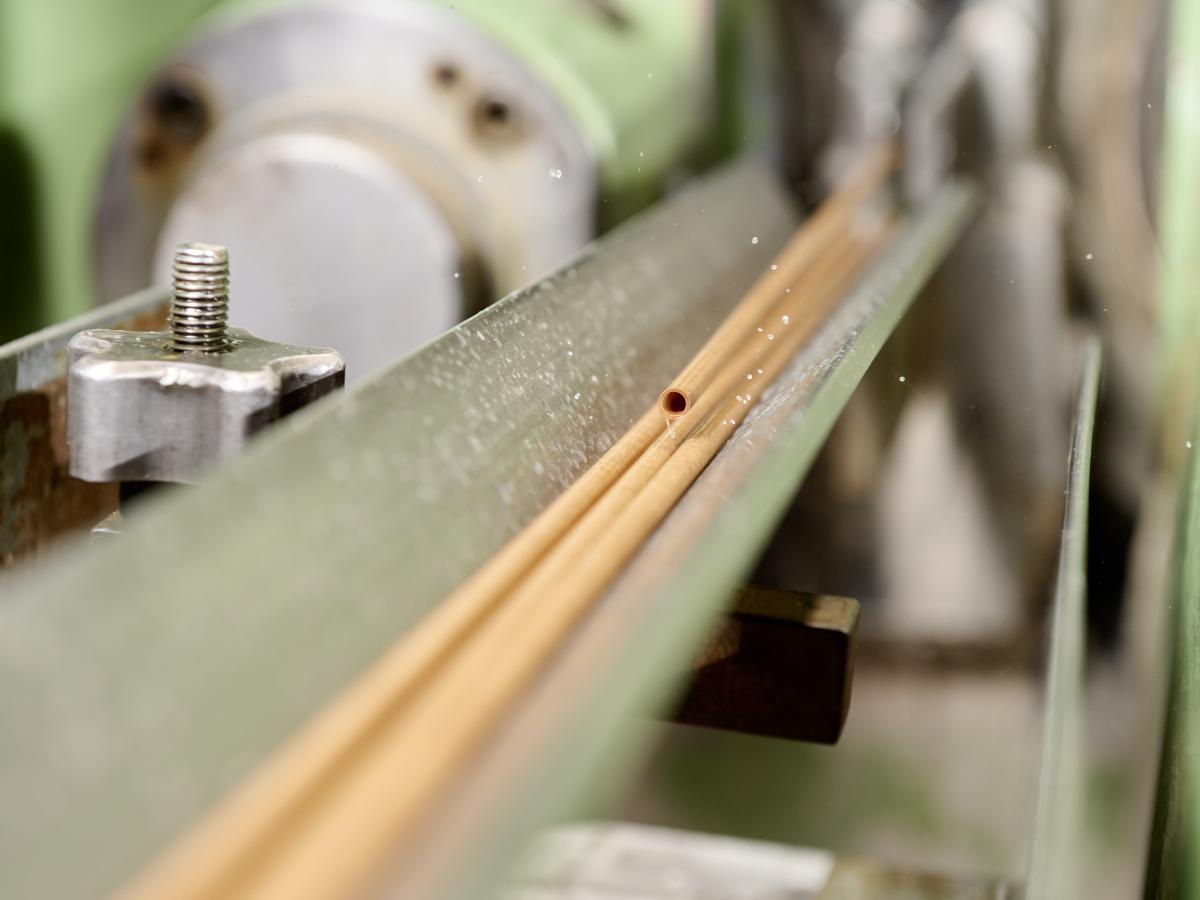

Krempel is one of the largest European manufacturers of composite tubes for use in Industry, Automotive, Railway, Medical, Aerospace & Defence. The company’s own composite materials are used to manufacture convolute wound tubes that are then manufactured into machined products, including phenolic resin ball bearing cages, using the latest 5 and 9-Axis CNC processing machines.

High-performance composite tubes and precision components – customised to your requirements

Krempel is one of Europe’s largest producers of composite tubes and has the capability to produce mandrel wound tubes with external diameters from 4.5 mm to 600 mm, from 2.35 mm internal diameter, and up to 3000 mm in length. These tubes can be precision machined to customer specification.

Our wide range of tubes combine the best material properties for optimised product performance. Standard materials available include phenolic cotton, silicone glass, epoxy glass, phenolic paper, mica and epoxy cotton. Our more specialised range includes resin impregnated aramid, melamine glass, polyester and carbon fibre.

Krempel also has the know-how to manufacture formed tubes such as square or rectangle and hybrid constructions to customers’ requirements. Due to their special properties composite tubes are an ideal alternative for traditional materials such as steel or aluminium.

For welding equipment we offer a wide range of parts such as nozzle insulators, torch bodies, thread protectors, swirl baffles/rings, heat shields, deflectors, plungers, switch and impeder casings. Not only do we have the benefit of excellent moulding and machining capabilities, we also manufacture the composite tubes from which the nozzles and other components are produced.

Benefits

- High strength and stiffness

- Lightweight

- Excellent machining properties

- Excellent temperature, UV, chemical and corrosion resistance

- Long durability

- High performance and reliability

- Very good price-performance ratio

- Flexibility and versatility in design

Key features

- Technologies: convolute winding, filament winding, spiral winding

- Fibres: aramid, carbon, cotton, glass, mica, paper, polyester (others on request)

- Resins: epoxy, phenolic, polyester, silicone, melamine (others on request)

- Tube lengths: up to 3000 mm

- Outside diameter: 4.4 mm to 600 mm

- Inside diameter: 2.35 mm to 550 mm

- Operating temperatures: up to +850°C

Areas of application

- Bearing Cages

- Welding Nozzles

- Bushings

- Spacers

- Insulating Sleeves

- Medical Devices

- Electrical Insulation Components

- UAV (Unmanned Aerial Vehicle)

- Aircraft Structural Components

- Radar & Antenna Housings

Quality you can trust

Krempel stands for high quality that not only complies with, but often surpasses all common international standards. We are accredited to ISO 9001 as well as AS 9100 and are members of the ADS, Hellios- JOSCAR and SC21. Additionally we have a full inspection capability that includes 3D Scanning, CMM and traditional processes.