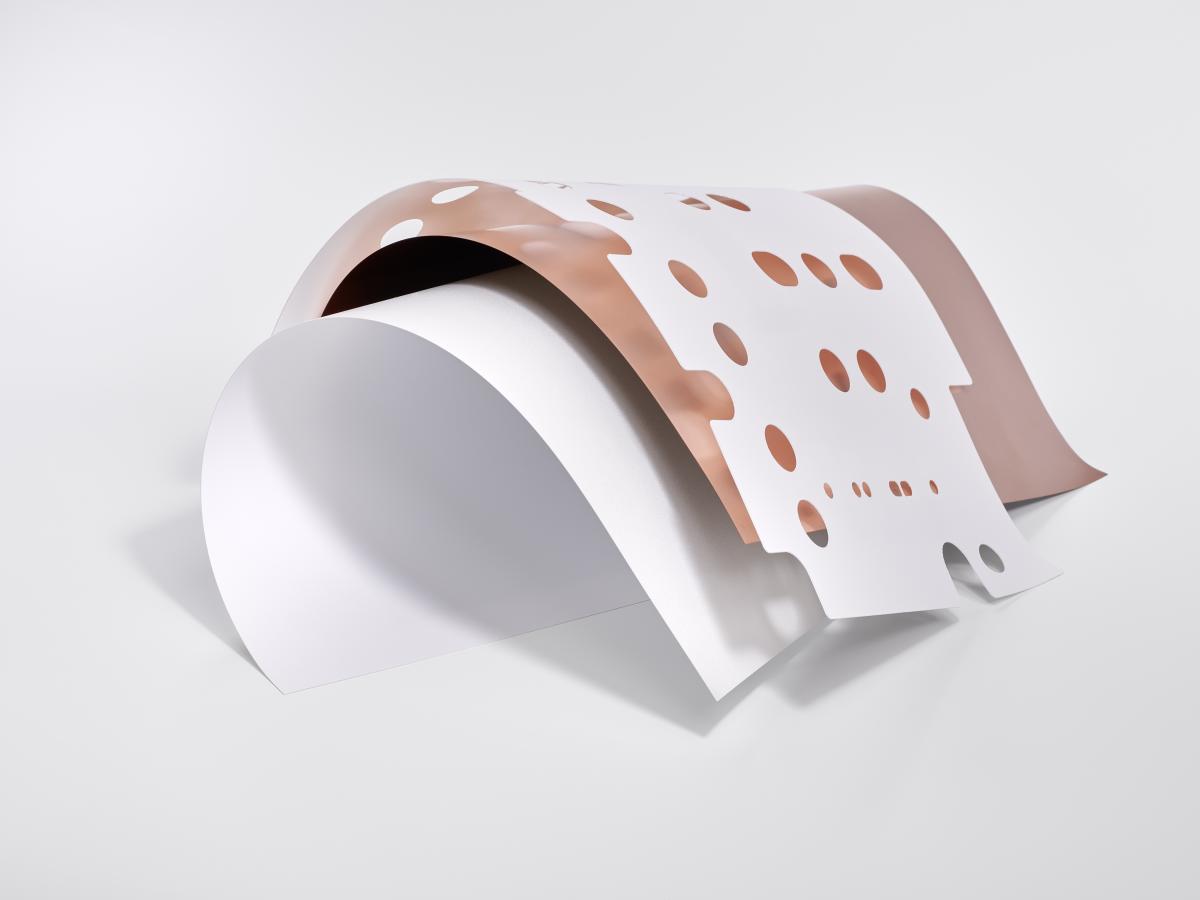

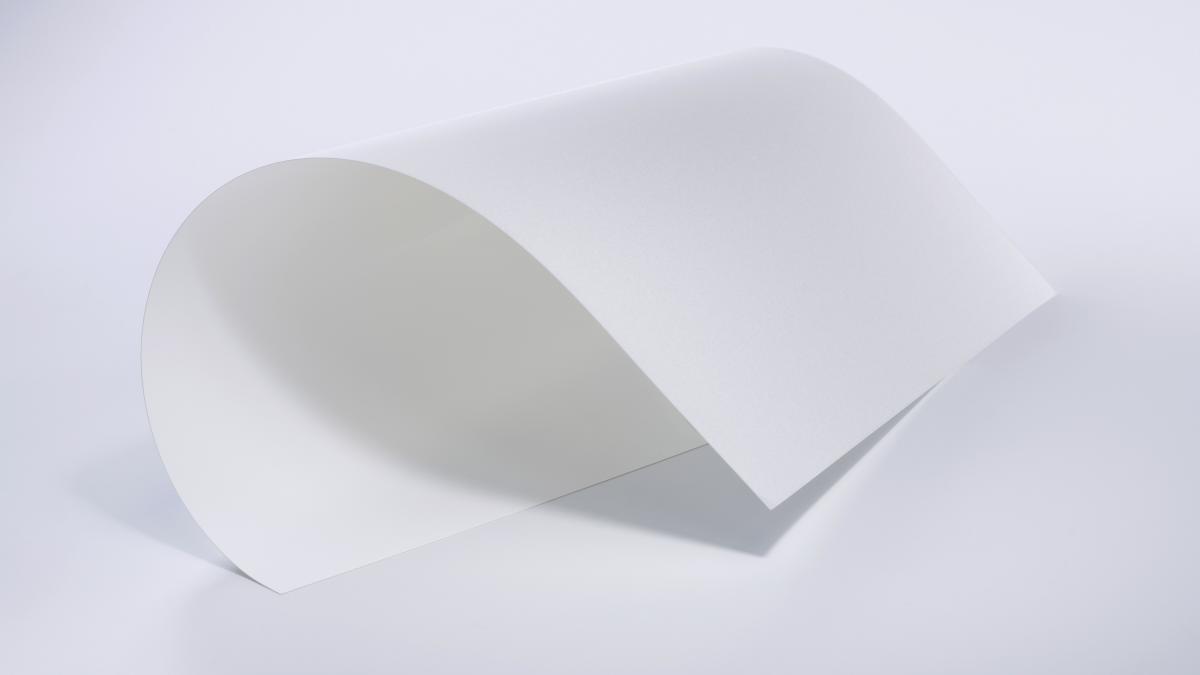

We have an extensive portfolio when it comes to busbar insulation, which covers a broad area of application – both films for less sensitive standard applications and high-performance versions for the highest demands for high temperature classes. Our standard portfolio includes busbar insulation with a nominal thickness of 125 µm and 185 µm for temperature classes A (105°C) and B (130°C).

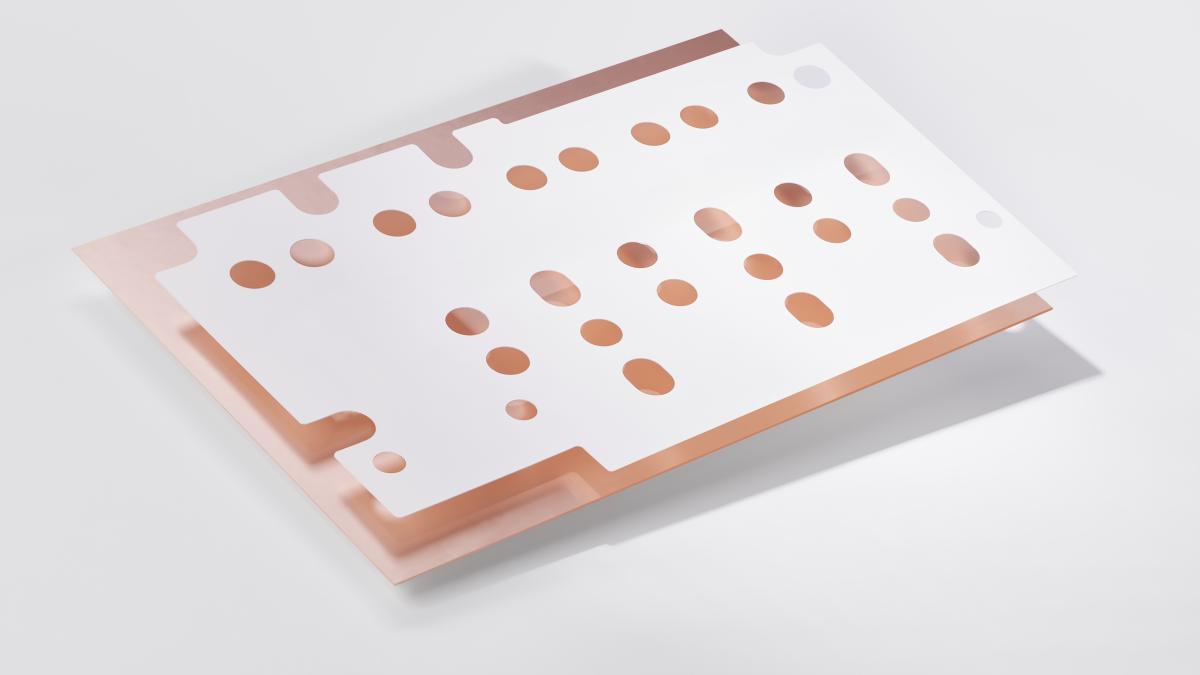

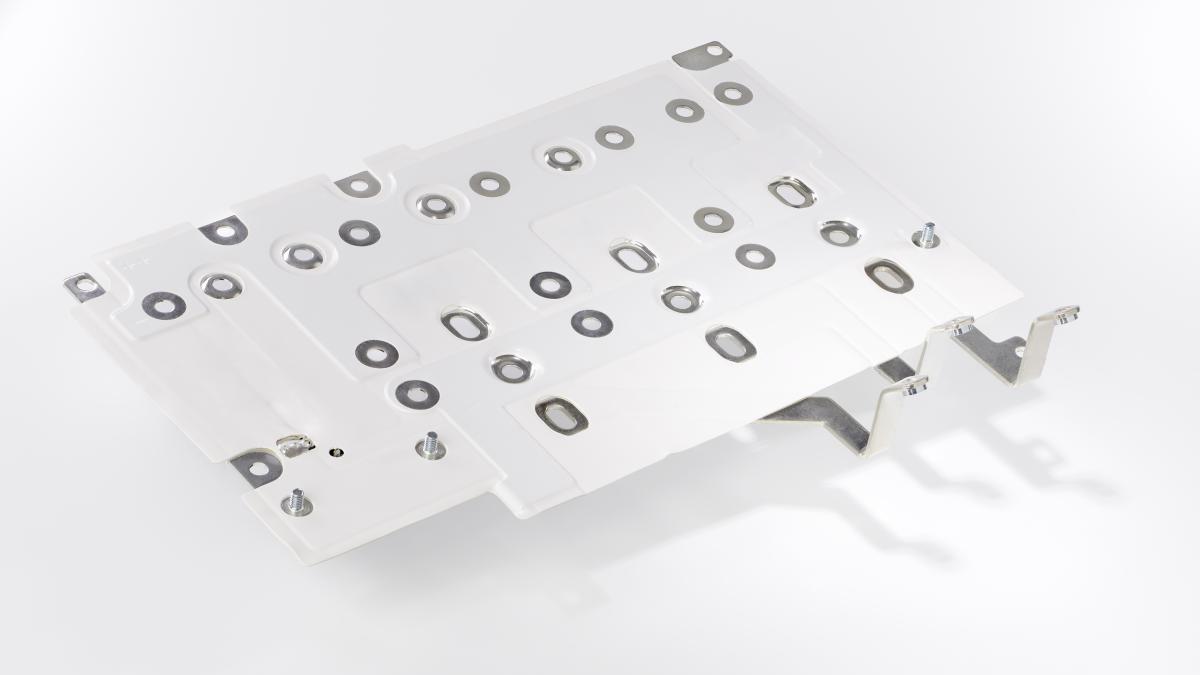

Depending on the temperature class and the requirements, the result can be special combinations of polymer films (dielectrics) and single-sided or double-sided adhesive systems. The single-sided or double-sided adhesive system allows rapid further processing and lasting adhesion. In order to guarantee optimal technical properties such as rigidity and dialectric strength, we only work with selected, low-shrinkage polymer films:

- PET

- Polyimide

- Nomex®

- Tedlar®

Our electrical insulation films fulfil all of the requirements of UL61800-5-1. This means that there is a cost- and time-saving route to UL508C certification of your end products available to you.

Busbar insulation from Krempel

You can have confidence in this:

- The best insulation properties

- Temperature-resistant up to 130°C. Temperature class B according to UL

- UL listing (OCDT2.E488244)

- Flame retardant according to UL

- RoHS compliant according to 2011/65/EU

- REACH compliant

- Highly flexible

- Excellent adhesion properties

- Easily removable protective film

- Suitable for punching, cutting, drilling and soldering processes

- Laminable through pressing

- Halogen free

- Wide variety of materials

Our standard portfolio

|

Material |

Adhesive |

Temperature class |

Total thickness (µm) |

Film thickness (µm) |

Adhesive thickness (µm) |

Total surface weight (g/m³) |

|---|---|---|---|---|---|---|

| PET | one-sided | A (105°C), B(130°C) | 155 | 125 |

33, 30 |

215 |

| PET | double-sided | A (105°C), B(130°C) | 185 | 125 | 30 | 250 |

| PET | one-sided | A (105°C), B(130°C) | 215 | 185 | 30 | 300 |

| PET | double-sided | A (105°C), B(130°C) | 245 | 185 | 30 | 335 |

Contact us for higher temperature classes or individual requirements. We will find you the right busbar insulation for your specific area of application.