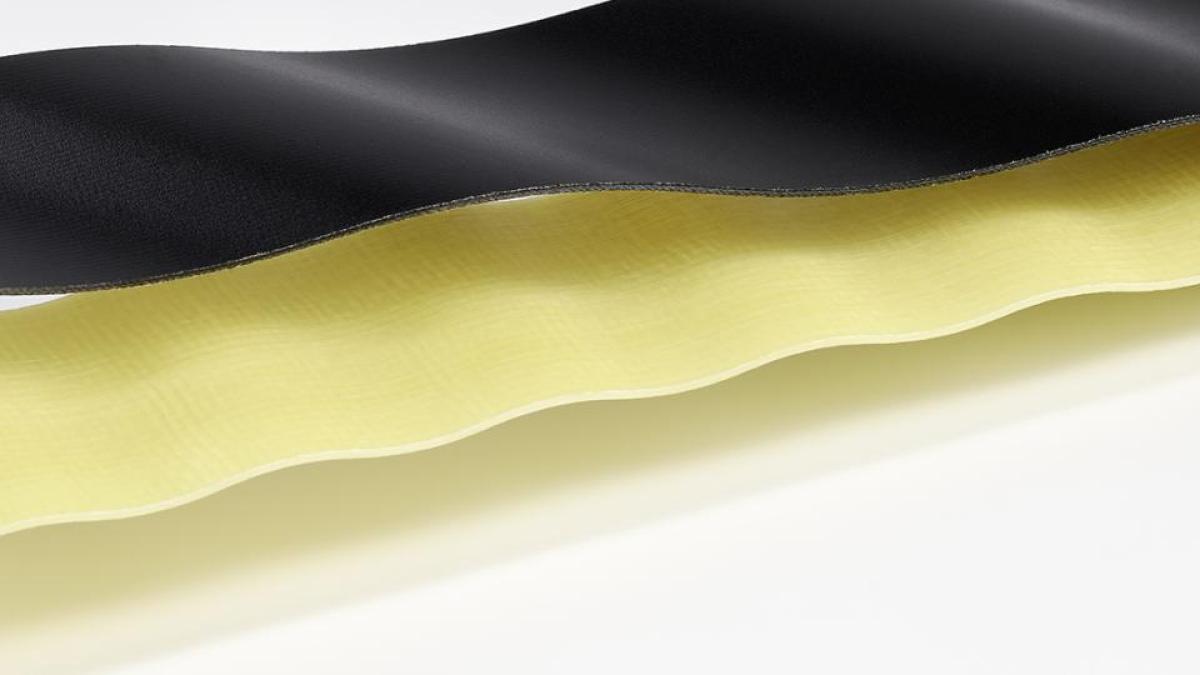

Side ripple springs ensure secure contacting between the electrically conductive corona shielding on the winding rods and the laminated core in the case of temperature-related dimension changes.

Top ripple springs have a damping function and ensure the secure fixing of the winding rods and the compensation of dimension changes in the radial slot direction caused by thermal influences.

Our ripple springs can be easily pushed into the slots thanks to the spring path. This makes the installation of the winding rods safe, cost-efficient and significantly quicker.

Our unique Krempel ripple spring system

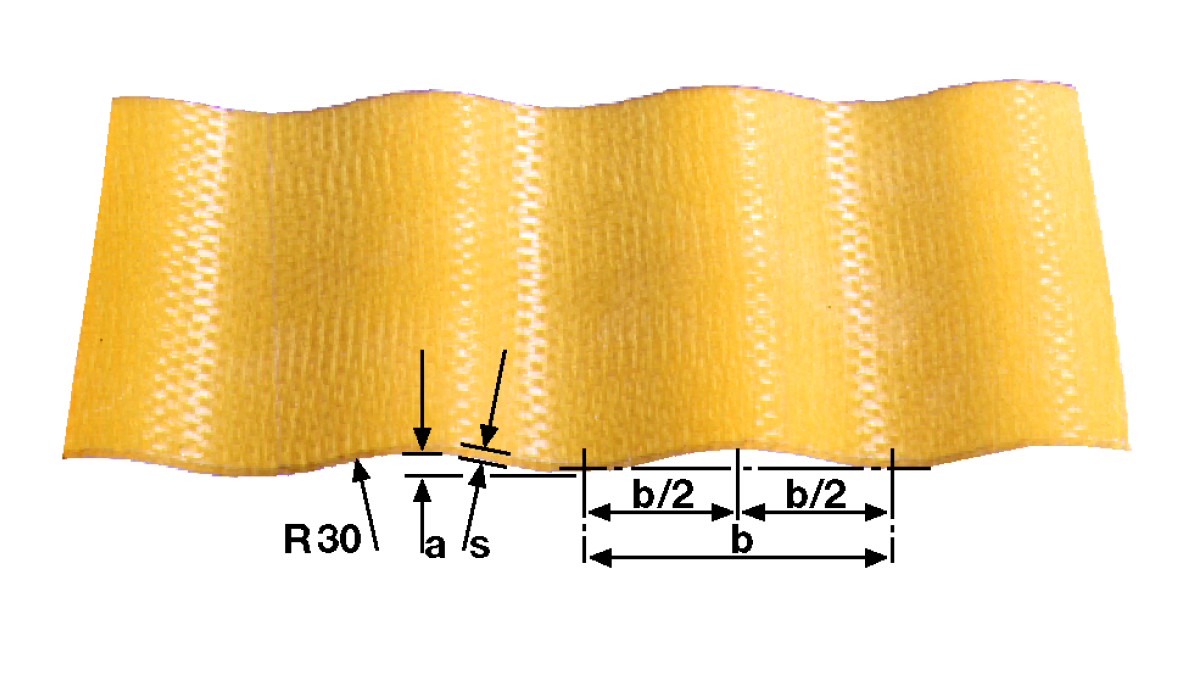

Top ripple springs

Top ripple springs provide the mechanical securing element in the slot closure area thanks to the interplay between the spring effect and the electrical insulation.

The structure and geometry of the Krempel top ripple springs mean that they meet the requirements of high-voltage technology. The spring characteristic curve has an almost linear progression up to 65% of the spring path. The bending stress that occurs when the top ripple spring is flattened is lower than the associated bending strength of the material. This is important because the top ripple spring is compressed to approx. 80% of its spring path when being fitted into the slot.

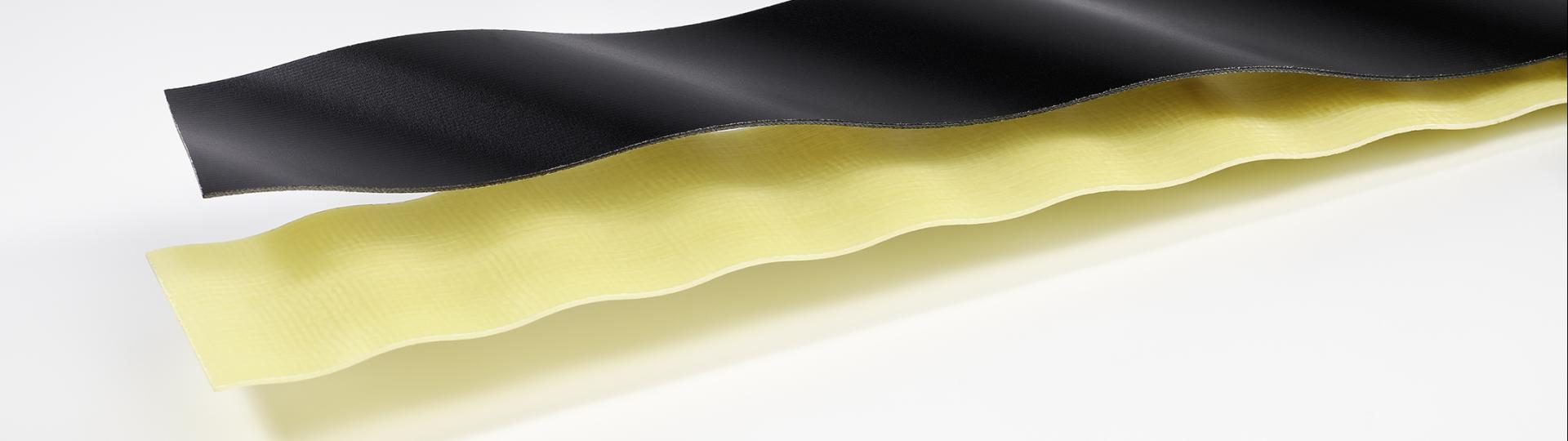

Side ripple springs

Side ripple springs from Krempel provide the electrical and mechanical securing element in the slot side area thanks to the interplay between the spring effect and the electrical conductivity.

The structure and geometry of the Krempel side ripple springs mean that they meet the requirements of high-voltage technology. The spring characteristic curve has an almost linear progression up to 50% of the spring path. The bending stress that occurs when the side ripple spring is flattened is lower than the associated bending strength of the material. This is important because the side ripple springs are largely pressed flat when being fitted into the slot.

Applications

Side ripple springs

Our electrically conductive side ripple springs serve as side slot fillers in stator windings in hydropower and turbo generators. They ensure good contacting between the conductive winding surface and the iron core.

Top ripple springs

Our electrically insulating top ripple springs are used in hydropower and turbo generators to fix the bar windings and to provide a damping effect in the radial slot direction.