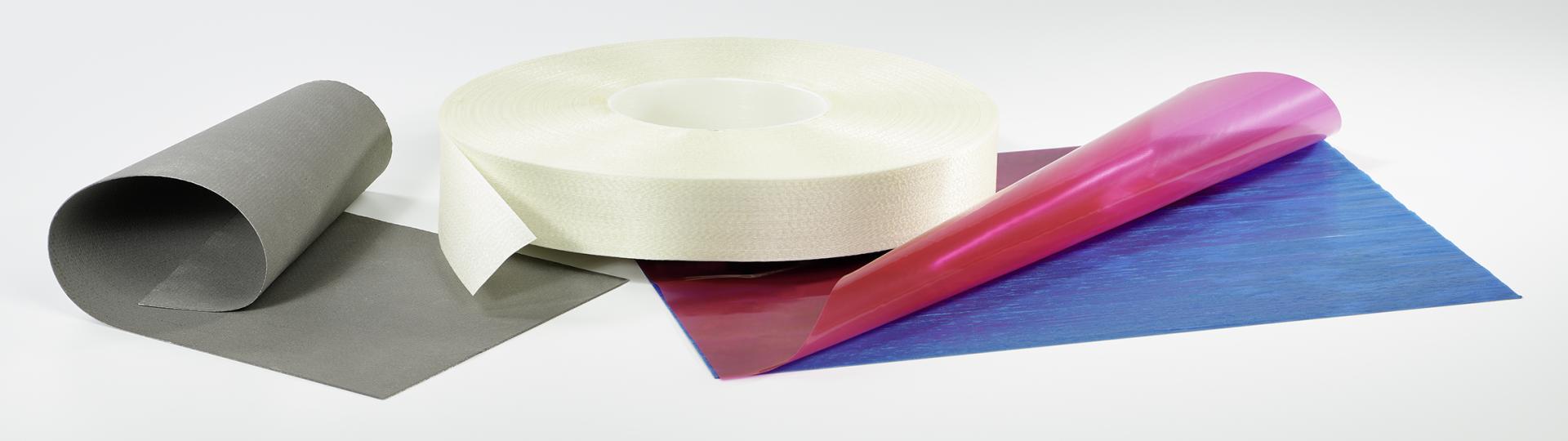

Prepregs (PREimPREGnated) and UD prepregs (UD= unidirectional) from Krempel are based on reactive resins with a curing system that is latent at room temperature and highly reactive at elevated temperatures.

Different impregnation technologies are used to impregnate fabrics, nonwovens, rovings and scrims with specially adapted resin systems. Based on these thermosetting resin systems, Krempel produces prepregs with all common fibre types, such as glass, carbon, basalt or aramid fibres. Natural fibres, nonwovens and papers as well as hybrid or combined structures complete our diverse portfolio. These fabrics, which are also developed or adapted to customer specifications, make us a highly specialised partner at your side.

All resin systems are possible with reinforcements according to your wishes and requirements. Examples are:

- Fabric made of carbon or glass fiber (E or S glass)

- Multiaxial fabric made of carbon or glass fiber

- Aramid fabric

- Non-Woven Fabrics (NCF)

- Natural fibers

- Hybrid fabric

We would be happy to offer you other options on request.

PREPREG systems from Krempel

Expoxy resin systems, phenolic, thermoplastic or highly specialised systems

EPOXY RESIN SYSTEM

BE System

The fast processing prepregs are based on a temperature resistant modified epoxy resin with low tack and no to low tack.

This system is suitable for both sheet production and components.

BD Sytem

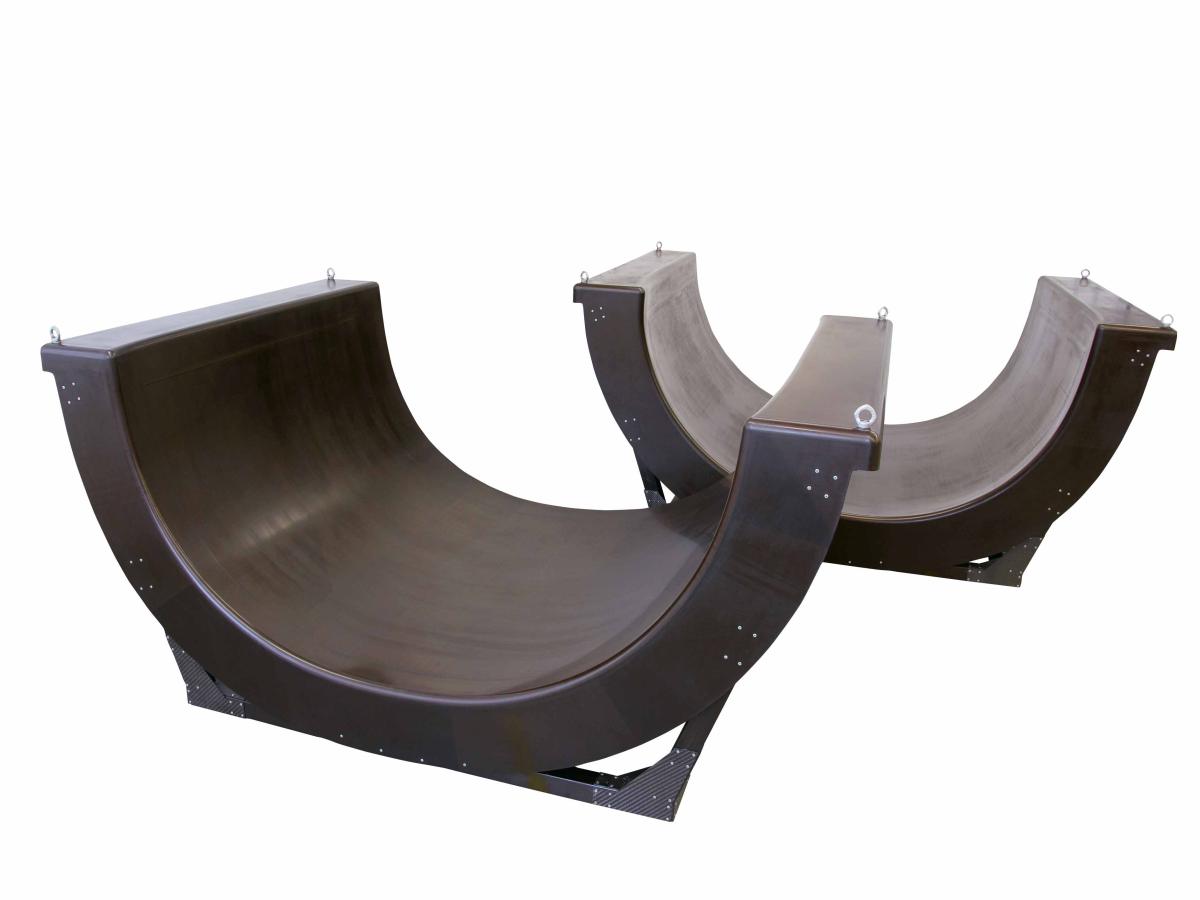

The prepregs of the BD system are based on modified epoxy resins with high impact strength and excellent dynamic properties. They can be processed into high-strength structural components using all common methods. The curing range is between 85 °C and 140 °C; the max. heat resistance is 125 °C. Available as unidirectional or fabric-reinforced prepreg.

Prepregs produced using the BD system are suitable for structural components. They can be moulded quickly and are also characterised by their very good mechanical properties.

BX System

The prepregs of the BX system are based on modified epoxy resins with an extremely wide curing range of 55 °C to 185 °C and meet the requirements of a low-pressure/low-temperature prepreg.

The BX system is suitable for the production of structural components as well as for mould making. Fibre composite moulds and components have a heat distortion temperature of 195 °C. Processing can be carried out according to all common methods.

RESIN SYSTEM PHENOL

PD

Krempel offers prepregs for all areas and applications such as sandwich components, interior in the aerospace and railway sector with increased fire protection requirements. Ask for our solutions according to EN 45545 HL3 R1/R7 and FAR 25.853.

Krempel supplies sticky or dry PREPREGS optimised for customer-specific processes such as crushed core or hot in hot out processes. These are optimised for minimum free formaldehyde content and have improved emissions for increased occupational safety.

Also ask about our modified phenolic resin PREPREGS with optimised ballistic behaviour.

SPECIALTIES

Krempel offers high-performance resin systems with special property profiles for e.g. high temperature and low temperature applications, excellent mechanical and electrical properties, good hydrolysis and chemical resistance.

Customized thermoplastic materials complete our portfolio.

Further information is available in our brochure "PREPREG resin systems".

Downloads

Flexible Prepregs and Sheets

Flexible Prepregs and Sheets - excellent Dynamic & mechanical Properties; phenolic resin-based flexible Composites

PREPREG Resin Systems

PREPREG Resin Systems