Our range of services at a glance

Build-to-print partner:

Based on your production drawing, we manufacture the component precisely and on time – from single pieces to small series, in proven quality and using state-of-the-art technology.

Build-to-spec partner:

You provide the specifications, we develop the appropriate design drawing and use it to produce the finished component – efficiently, precisely and from a single source.

Solution Partner:

If you are facing a technical challenge and do not yet have a concrete implementation idea, we will work with you to develop a customised solution – tailored precisely to your requirements.

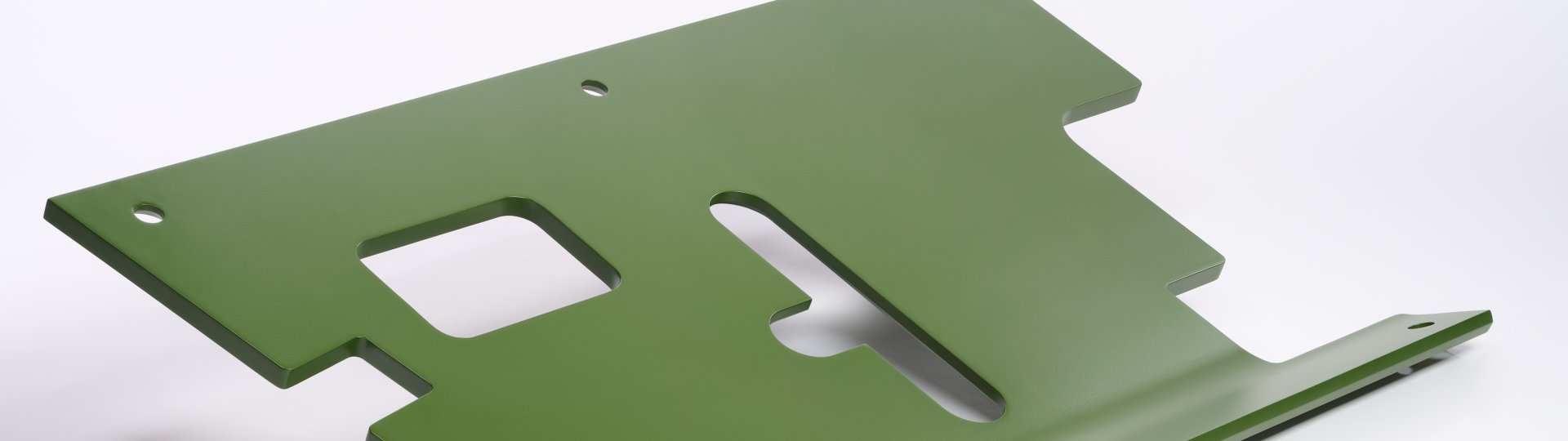

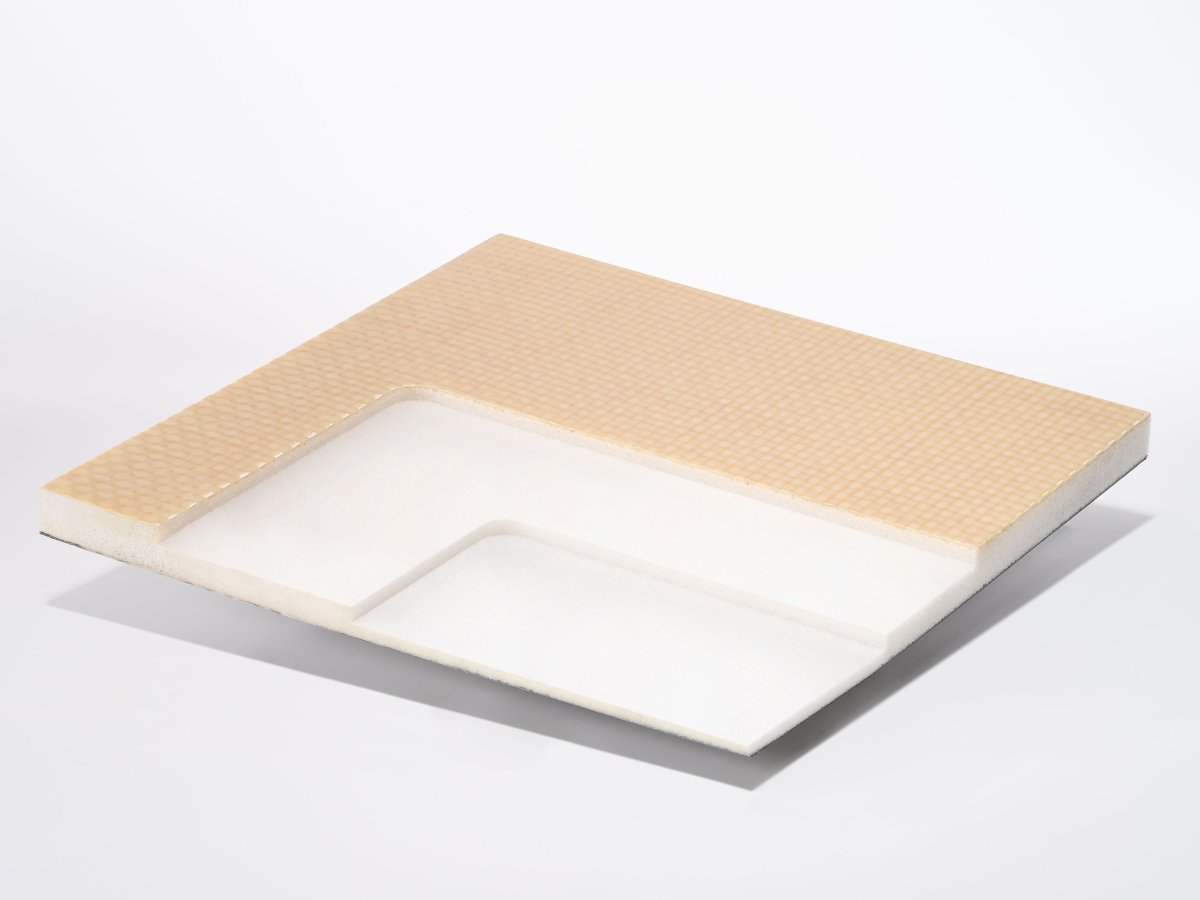

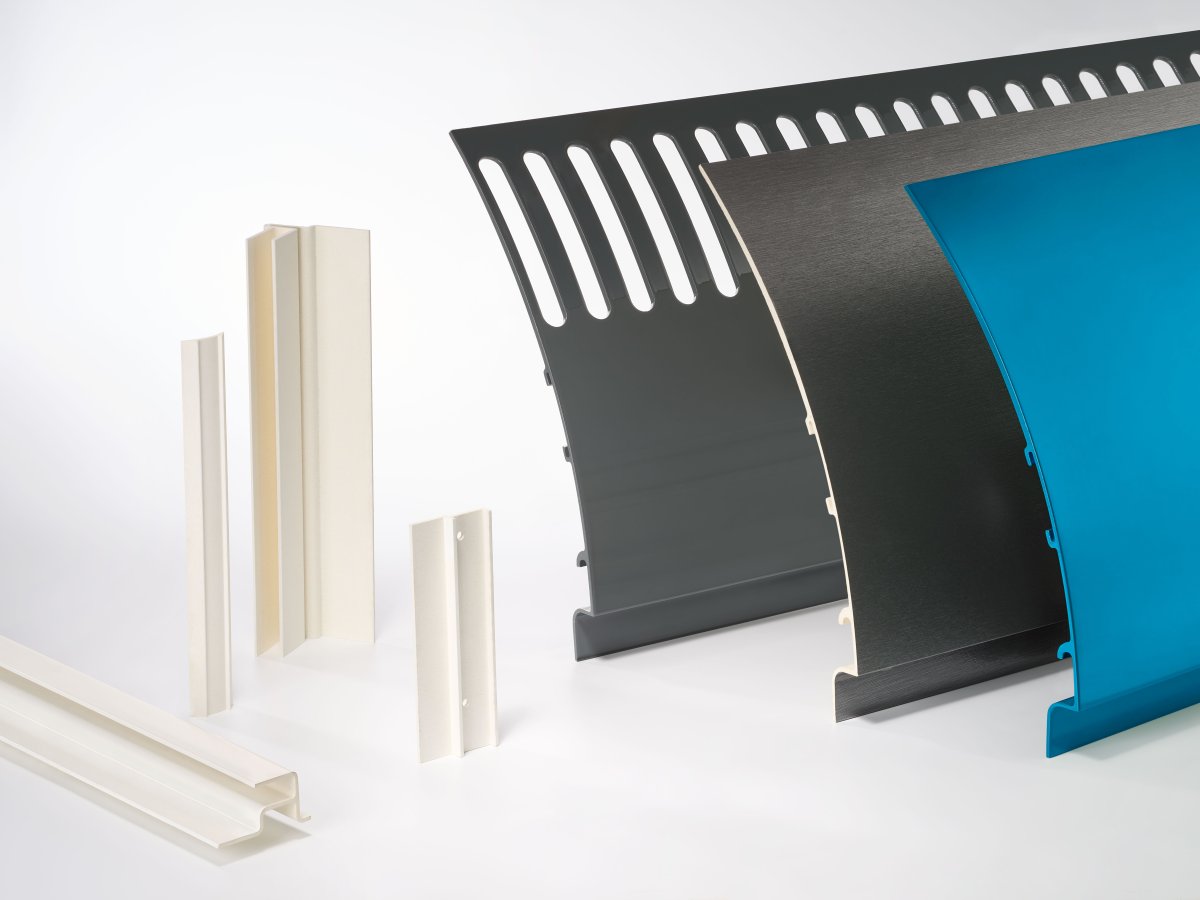

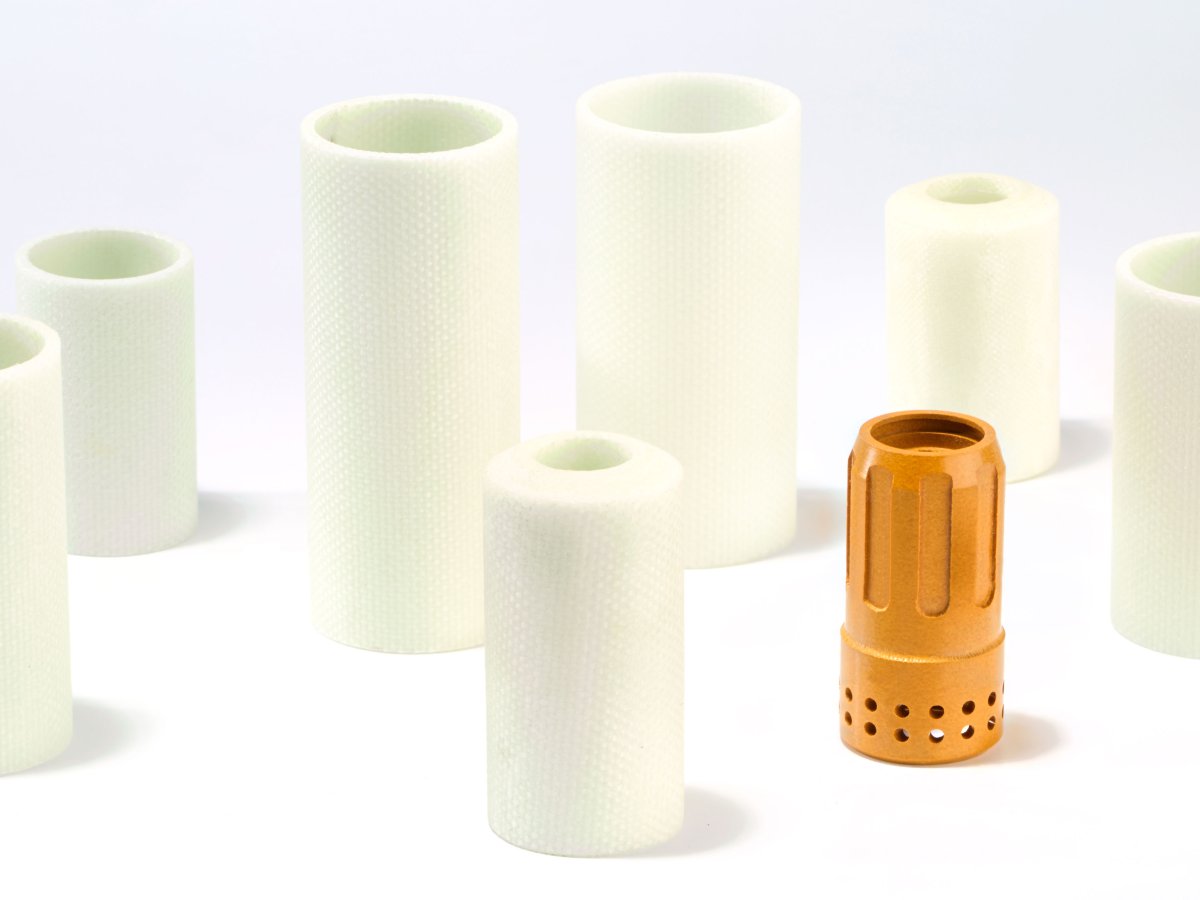

Customised composite materials – for your specific application

Whether bulletproof walls, flame-retardant battery housings, C-arms for modern X-ray technology or radomes to protect sensitive antenna and radar systems – our possibilities are limitless.

With comprehensive manufacturing expertise and innovative thinking, we accompany you from the initial idea to the production-ready product. We rely on close cooperation to realise tailor-made and economical solutions.

Whether it's a single piece or a large series, our developments fit seamlessly into your existing structures – functional, reliable and precise.

Our solutions in use

- Protection Technology: Ballistic components that reliably protect human lives and sensitive technology.

- Healthcare: Functional components that specifically support healing processes.

- Railway: Sustainable mobility through innovative and flame-retardant lightweight components.

- Mobility: Reliable protection against environmental influences – for durable, robust systems.

- Aerospace: Certified components for exteriors/structures and interiors in accordance with aviation standards.

- Mechanical Engineering: Efficient material alternatives for classic components – lightweight, stable, durable.

- Industrial Solutions: Components with excellent thermal and mechanical properties.

- Energy: Customised insulation solutions for transformers – precisely tailored to OEM requirements.

What our components and assemblies deliver

- Insulation

- Shielding / electromagnetic compatibility (EMC)

- Ballistic protection

- FST fire protection

- Lightweight construction

- Chemical resistance

- Durability

- Coatings

Expertise in fibre composite technology

At our highly specialised sites in the United Kingdom (Bideford) and Germany (Vaihingen/Enz and Zwönitz) as well as in Brazil, we offer a comprehensive range of services for demanding industrial applications. We provide tailor-made solutions made of composite materials, thermoplastics and thermosets – from the initial idea to the finished component or assembly.

Materials and manufacturing technology

- Laminating (prepreg, wet laminate)

- RTM / infusion (resin transfer moulding, resin infusion, injection moulding/overmoulding)

- Plate and compaction presses, SMC (Sheet Moulding Compound) up to 350 tonnes

- Autoclaves and ovens for temperatures up to 230°C, pressure up to 16 bar, diameter up to 2.5 m x 10 m length

Mechanical processing

- CNC machining with up to 9-axis machining (milling, turn-milling) including MAKA systems with large machining area

- Water jet and cutting systems Table sizes up to 4 m x 3.2 m (air-conditioned & deep-freeze capable)

Design & training

- CAD formats: CATIA, Pro/E, NX, STEP, STL and many more

- Internal FRP training

Component manufacturing & toolmaking

- CFRP/GFRP/FRP construction methods, autoclave technology, prepreg processing, organic sheets

- Fixture construction, repair, test gauges

Assembly & finish

- Sandwich construction methods, structural bonding, support structures

Measurement & testing technology

- 3D scanning, CMM measurements, Faro measuring arm (3.7 m length)

- Material tests: tensile testing, gloss level, surface roughness

Clean room production

- Two climate-controlled clean rooms for sensitive applications

Certified quality

- Our production is certified according to: ISO 9001, ISO 9100 and DIN 6701/2304