From fibre composites to functional films

Our materials form a coordinated system: prepregs and UD prepregs offer maximum mechanical performance and design freedom in lightweight construction; Tedlar® films protect and refine surfaces with excellent chemical and UV resistance; organosheets complement the portfolio with thermoplastic semi-finished products that can be efficiently formed and recycled.

Together, they create solutions ranging from structural components to decorative and protective coatings – tailor-made, process-reliable and sustainable.

Materials with a system and tailored to your requirements

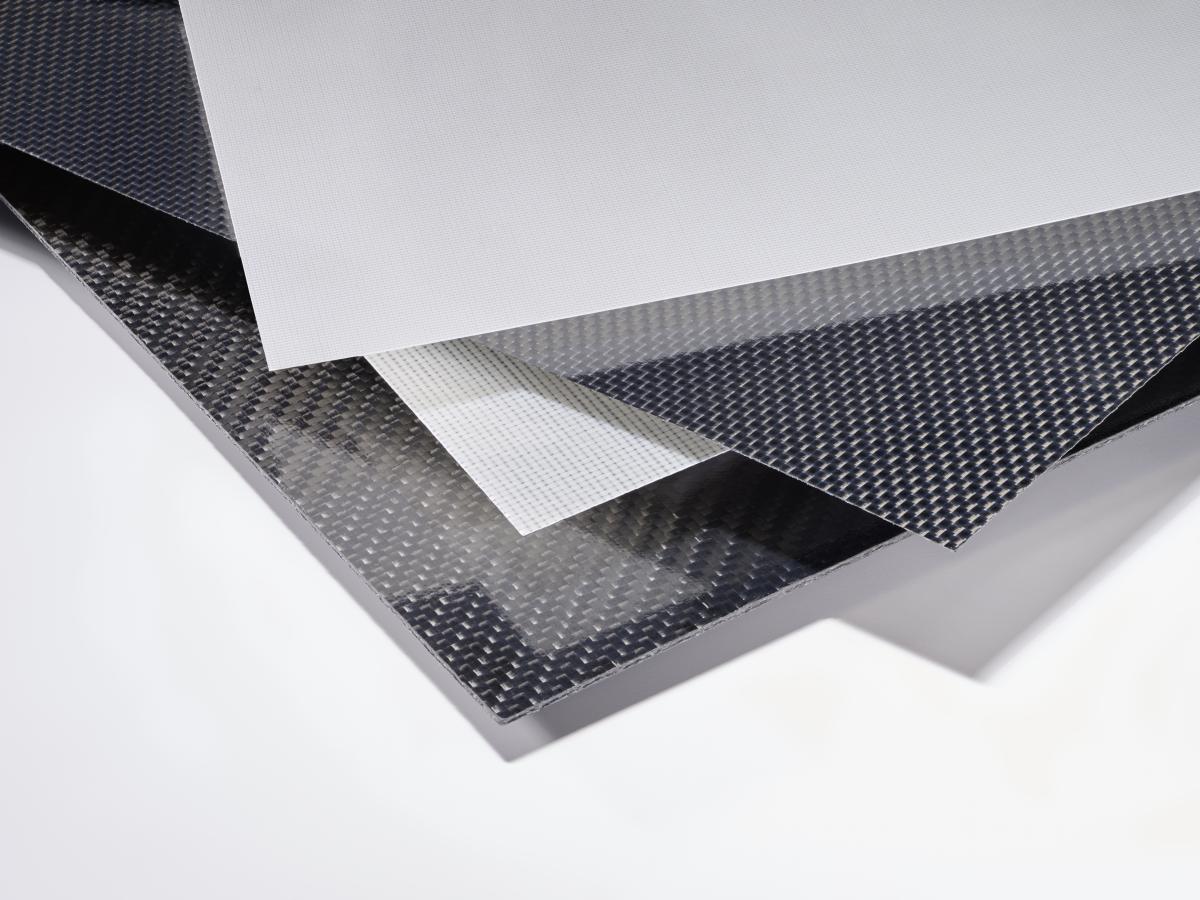

- Prepregs & UD prepregs: Impregnated semi-finished fibre products based on epoxy, phenolic or special resins for highly stressed structural and sandwich components.

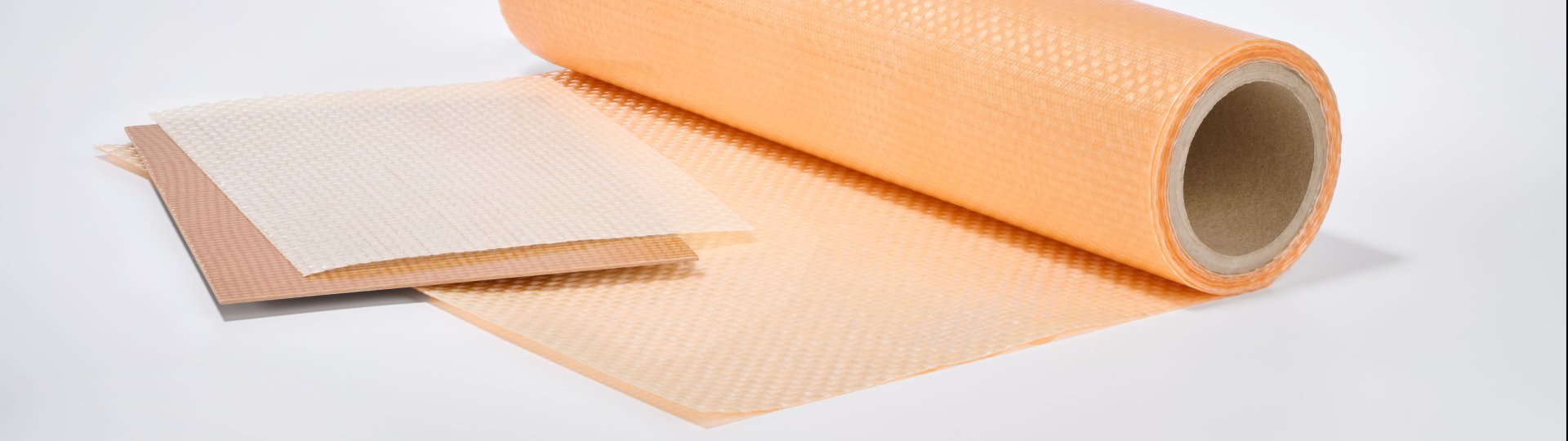

- Tedlar® films (PVF): Surface protection and decorative films with exceptional chemical, electrical and UV resistance.

- Organosheets (PREGNIT TP): Thermoplastic fibre composite sheets for dimensionally stable, re-formable lightweight components.

These material worlds complement each other perfectly: where prepregs provide maximum strength, Tedlar® films take over the permanent surface function and organosheets enable fast, series-ready forming. The result: holistic solutions from a single source.

Advantages at a glance

- Wide range of materials from thermosets to thermoplastics

- Compatible surface, protective and structural materials

- Proven quality "Made in Germany" and worldwide series production

- Sustainable processes, short cycle times, reproducible results

- Support from material selection to series production approval

Wide range of applications

Whether in electromobility, rail vehicle construction, energy technology or industrial manufacturing, our composite materials offer the optimal balance of weight, strength, chemical resistance and temperature resistance. Our experts work with you to develop tailor-made solutions that work in series production.