For demanding thermal environments

In today’s energy infrastructure, liquid-filled transformers are expected to deliver uncompromising reliability - even under extreme thermal stress, continuous overload, and elevated ambient temperatures. Traditional thermal management approaches, such as increased oil ducts or active cooling, often lead to larger, less efficient system designs.

Krempel offers a smarter solution: high-temperature insulation materials tailored for thermal classes up to 180 °C. These advanced materials ensure outstanding dielectric strength, mechanical stability, and long-term thermal endurance. Whether used in compact distribution transformers, renewable energy systems or e-mobility charging infrastructure, they enable optimized designs without compromising safety or performance.

Proven in both mineral and ester-based oils, and available in versatile formats, Krempel's insulation systems are engineered to meet the evolving demands of modern transformer technology.

Benefits at a glance

- Full thermal class coverage: Covers all thermal classes from 95 °C to 180 °C

- Excellent thermal endurance: Proven durability under long-term high temperature conditions

- Superior overload capability: Maintains insulation performance under thermal stress and peak loads

- Compact transformer design: Enables smaller and lighter transformers with high performance

- Reliable dielectric strength: Offers high electrical stability, even in critical environments

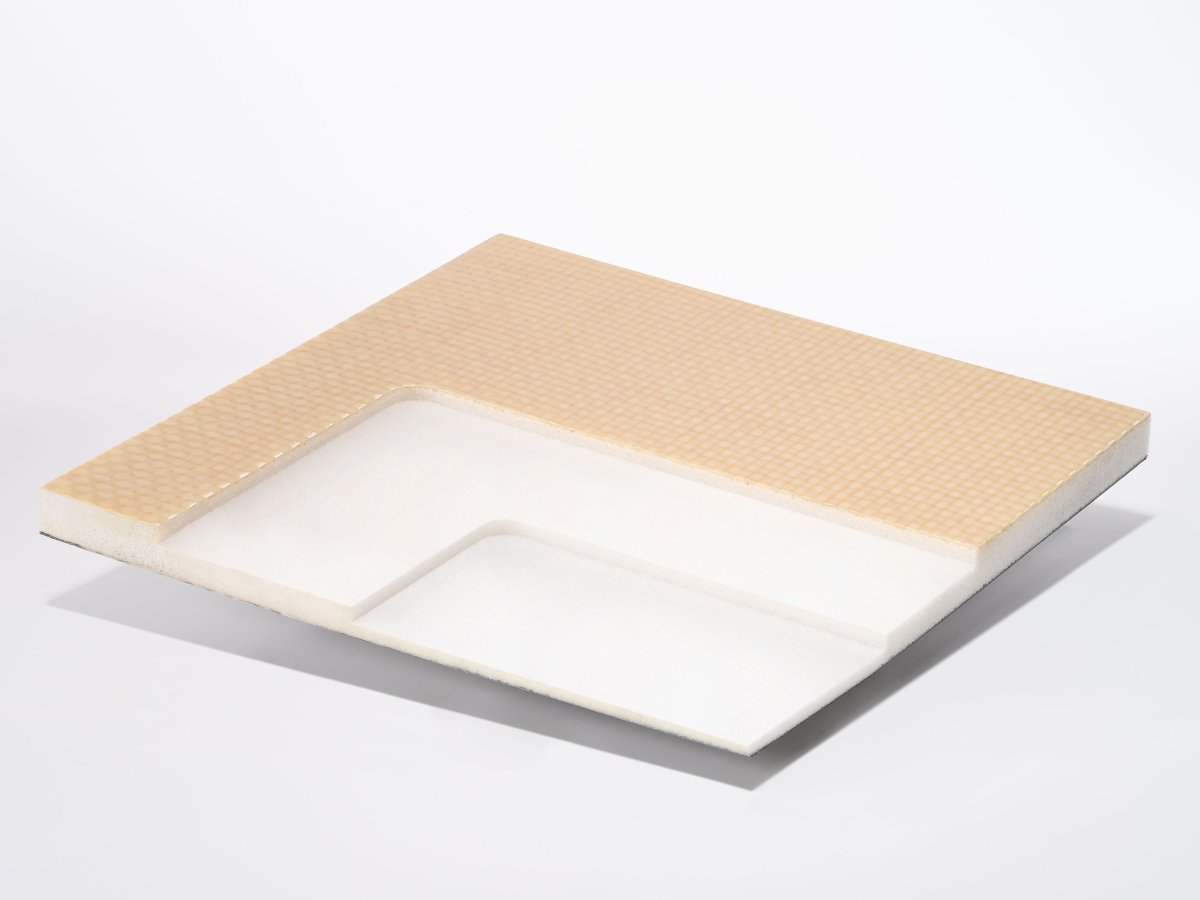

- Versatile material formats: Available as paper, multilayer laminates, or diamond dotted sheets

Krempel Presspaper TU for 130-140 °C

Krempel Presspaper TU is a high-grade thermally upgraded insulation paper designed for enhanced thermal stability and long service life in liquid-filled transformers. By introducing nitrogen into the cellulose matrix, the oxidation process is significantly slowed down - enabling reliable performance in thermal classes up to 130 °C (in mineral oil) and 140 °C (in ester fluids).

This presspaper offers superior dielectric strength and mechanical durability, making it ideal for coil winding, barrier insulation, and core or layer insulation. Its multilayer calendered structure ensures dimensional stability and processing efficiency even under high thermal stress.

Thermally upgraded Presspaper TU is also available as a diamond dotted version (DPP-TU) for advanced winding applications. Proven in demanding transformer environments, it represents a cost-effective step up from conventional kraft insulation.

Nomex® 910 - for thermal classes up to 140 °C

Nomex® 910 by Krempel is a high-performance insulating paper combining cellulose and aramid technologies. Engineered for thermal classes up to 140 °C, it bridges the gap between thermally upgraded kraft and pure aramid papers. This hybrid insulation offers enhanced electrical, mechanical and thermal properties – making it ideal for liquid-immersed transformers requiring higher reliability under medium thermal stress.

Developed for interlayer insulation and conductor wrapping, Nomex® 910 performs exceptionally well in both mineral and ester-based fluids. It ensures superior dielectric strength and thermal endurance proven through IEEE and IEC-based testing.

Manufactured by Krempel under license from DuPont™, Nomex® 910 is also offered as a diamond dotted paper (DPP-N910) for optimized processing and performance in modern transformer designs.

Krempel DPN410 - Pure aramid paper (up to 180 °C)

Krempel DPN410 is a premium diamond dotted insulation paper made from Nomex® pure aramid fibers. Specifically engineered for use in liquid-filled transformers operating under extreme thermal conditions, it meets the requirements of insulation class 180 °C.

Thanks to its excellent thermal endurance, DPN410 ensures long-term reliability even under high continuous loads and demanding environments. Its mechanical strength and dimensional stability make it ideal for applications such as layer and interlayer insulation, especially in compact transformer designs with high power density.

In addition to its outstanding electrical and physical performance, DPN410 offers excellent processing characteristics. It is used wherever conventional and hybrid insulation materials reach their thermal limits—making it the material of choice for maximum reliability and service life.

Download

High Temperature Solutions For Liquid Filled Transformers

Insulating materials for all thermal classes