Innovative Insulation for Powerful E-Motors

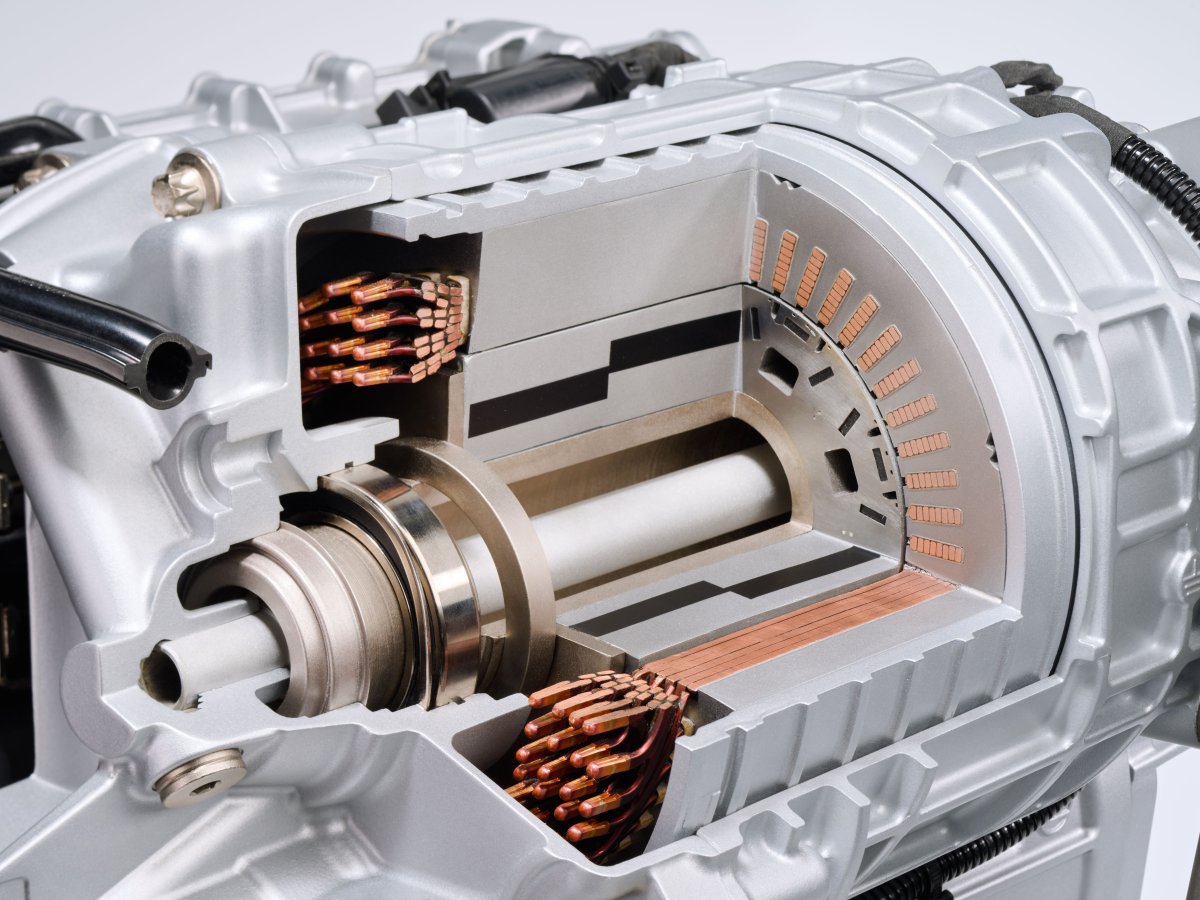

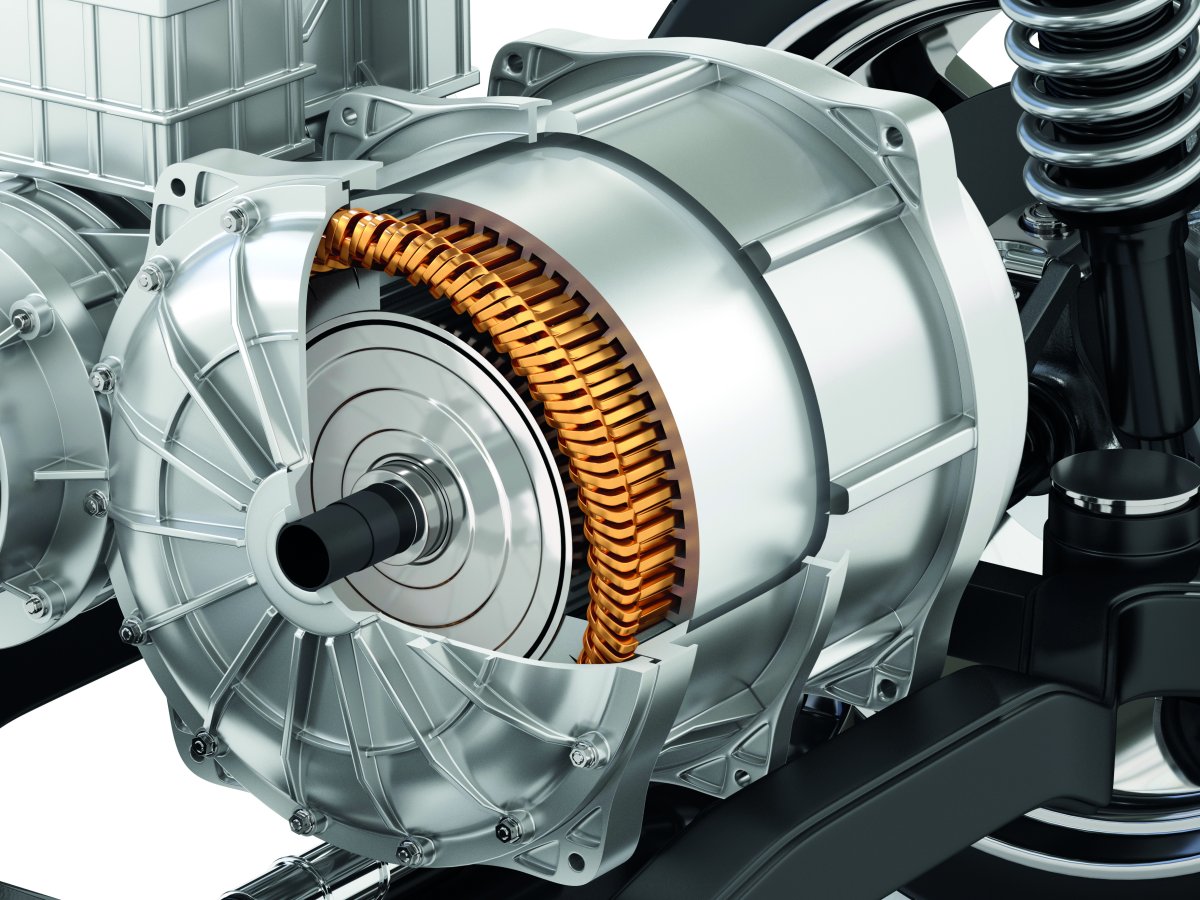

High-performance electric motors are a key to e-mobility. Higher voltages and power densities generate increased waste heat from mechanical friction and current-carrying conductors. This results in greater thermal stress on materials and components – and conventional air or water cooling reaches its limits.

The future therefore lies in intelligent thermal management through direct contact cooling: it efficiently dissipates heat and provides long-term protection for critical components such as insulation, potting compounds, winding heads, and magnets.

TRIVOLTHERM® E-Fluid-Safe is designed for motor insulation in established ATF transmission oils (Automatic Transmission Fluids) as well as in specially developed coolants for direct cooling – so-called e-fluids – which are playing an increasingly important role in motor cooling.

E-fluids place special demands on electrical insulation, as defined by IEC 63177 and T/CEEIA 415-2019. TRIVOLTHERM® E-Fluid-Safe exceeds these requirements in a unique way.

Benefits at a glance

- Full Standards Compliance: Fully meets the strictest requirements of IEC 63177 and T/CEEIA 415-2019

- Increased Efficiency: Optimizes thermal management and cooling, especially at high power density

- Outstanding Media Resistance: Resistant to aggressive cooling media such as ATF and e-fluids

- Excellent Thermal Performance: Stable under temperature fluctuations (+155 °C to −40 °C)

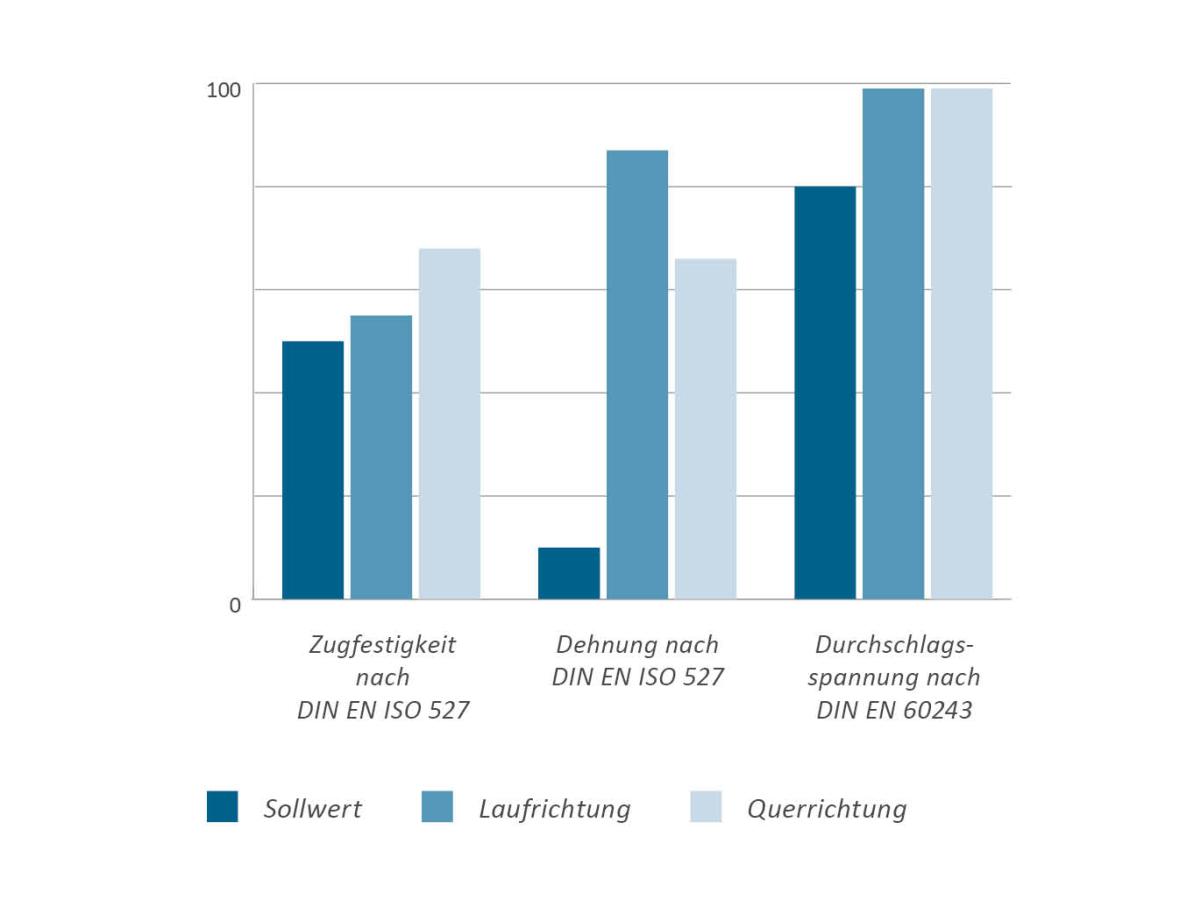

- Mechanical & Electrical Stability: Maintains tensile strength, elongation, and dielectric strength – even under extreme stress

- Form and Process Flexibility: Three-layer laminate available as rolls, sheets, die-cut parts, or hairpin tubes

High Performance for Direct Cooling

TRIVOLTHERM® E-Fluid-Safe has been specially developed for use in directly cooled electric motors. Typical applications include slot liners, slot closures, stamped parts, and interlayer insulation. The material impresses with excellent resistance to aggressive media and outstanding thermal performance.

We supply the three-layer laminate in rolls or sheets in customer-specific dimensions – ideal for seamless integration into your production process. In addition, we offer customized stamped parts and tubes with variable diameters for hairpin winding technology.

Maximum Reliability – Tested to International Standards

TRIVOLTHERM® E-Fluid-Safe fully complies with IEC 63177 and T/CEEIA 415-2019, developed by the International Electrotechnical Commission (IEC) and the Technical Committee on Energy Efficiency and Industrial Applications (T/CEEIA).

These standards define requirements and test procedures for insulation materials in stators, rotors, windings, and related components. They cover thermal resistance, mechanical strength, environmental resistance, and electrical performance.

Meeting these specifications is essential for reliable insulation under demanding conditions. TRIVOLTHERM® E-Fluid-Safe meets them in full, enhancing the reliability and service life of your electric motor components.

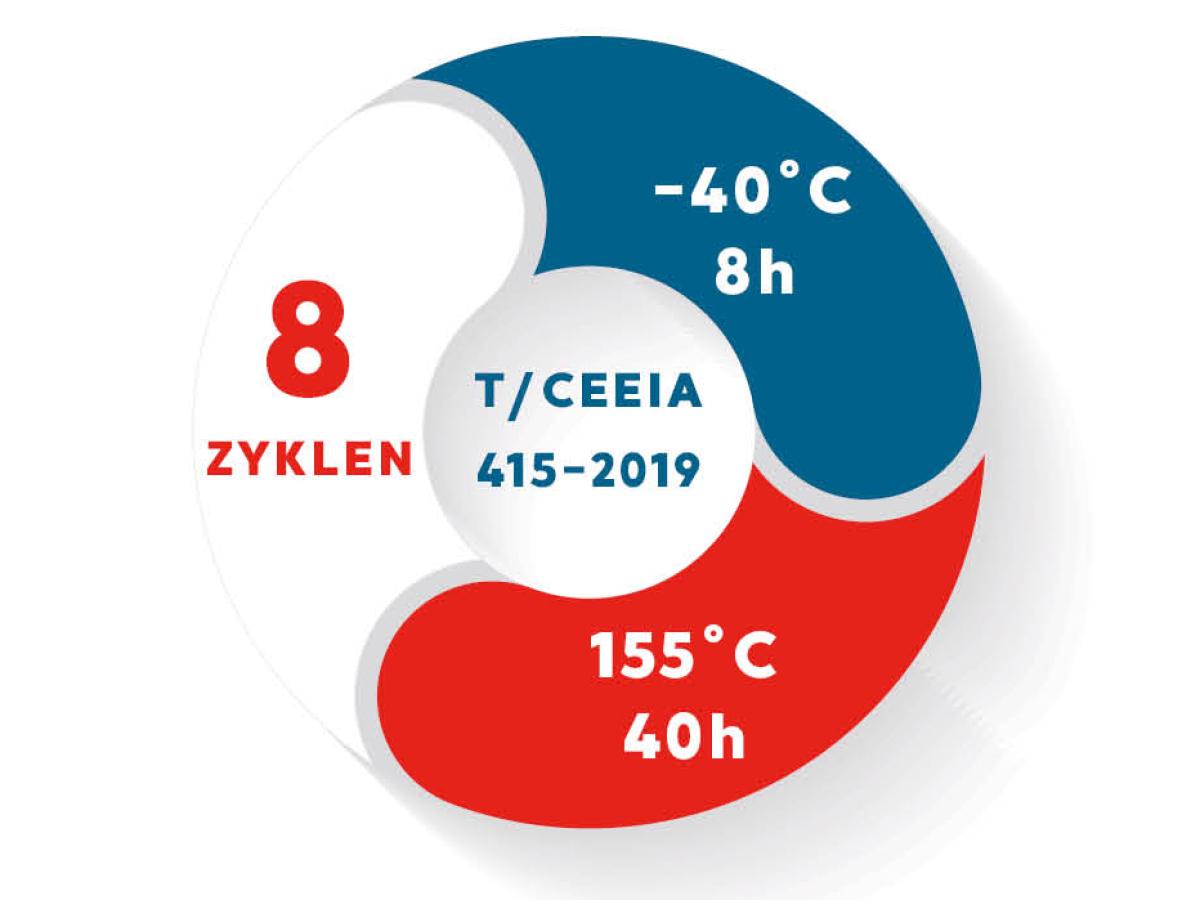

Test Procedure According to T/CEEIA 415-2019

The material is exposed in a hermetically sealed container to cyclic temperatures of +155 °C and −40 °C – with automatic transmission fluid (ATF) as the surrounding medium. After eight complete temperature cycles, TRIVOLTHERM® E-Fluid-Safe demonstrates outstanding property stability, exceeding the required limit values.

It reliably withstands the specified temperature ranges without any signs of degradation or decomposition. Critical properties such as tensile strength, elongation, and dielectric strength are largely retained at a high level.

Download

TRIVOLTHERM®-E-Fluid-Safe

Electrical insulation laminate for liquid cooled e-machines

Download

TRIVOLTHERM®-E-Fluid-Safe

Electrical insulation laminate for liquid cooled e-machines

KremGuard - Fire and Flame Safety

Epoxy prepreg system for maximum fire protection

High-performance materials for railway

High-performance materials for railway

KremSol Repair

Quick Solar Panel Repairs