Your Partner for High-Precision Bearing Cages and Customized Solutions

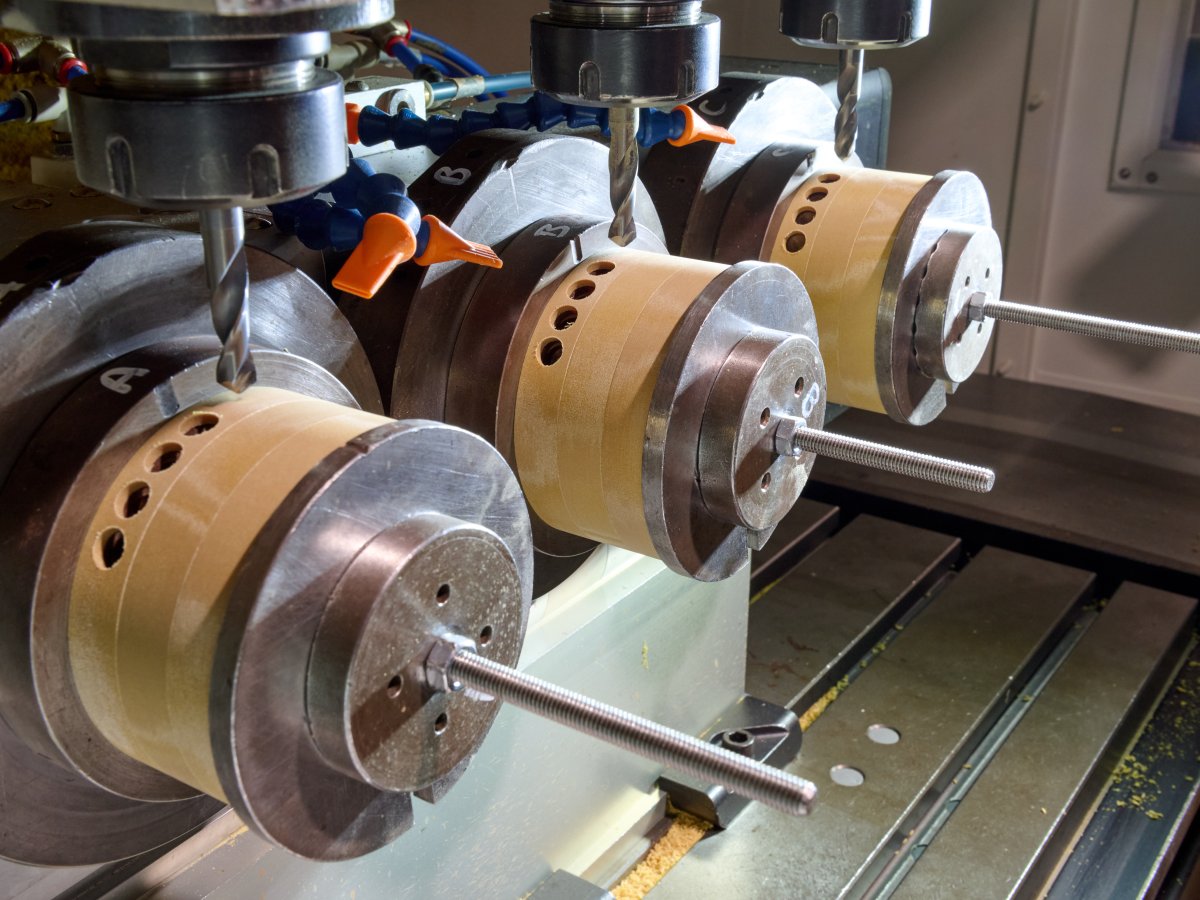

We manufacture a wide range of engineering polymer, hybrid and phenolic resin precision bearing cages for use in machine spindle bearings and other demanding applications. These cages are lightweight, low-friction, and dimensionally stable. Even at high speeds, they generate minimal heat. As a result, engineering polymer, hybrid and phenolic resin precision bearing cages are on par with those made of steel or aluminium. The range of applications extends from machine tools—such as lathes and milling machines—to dental drills.

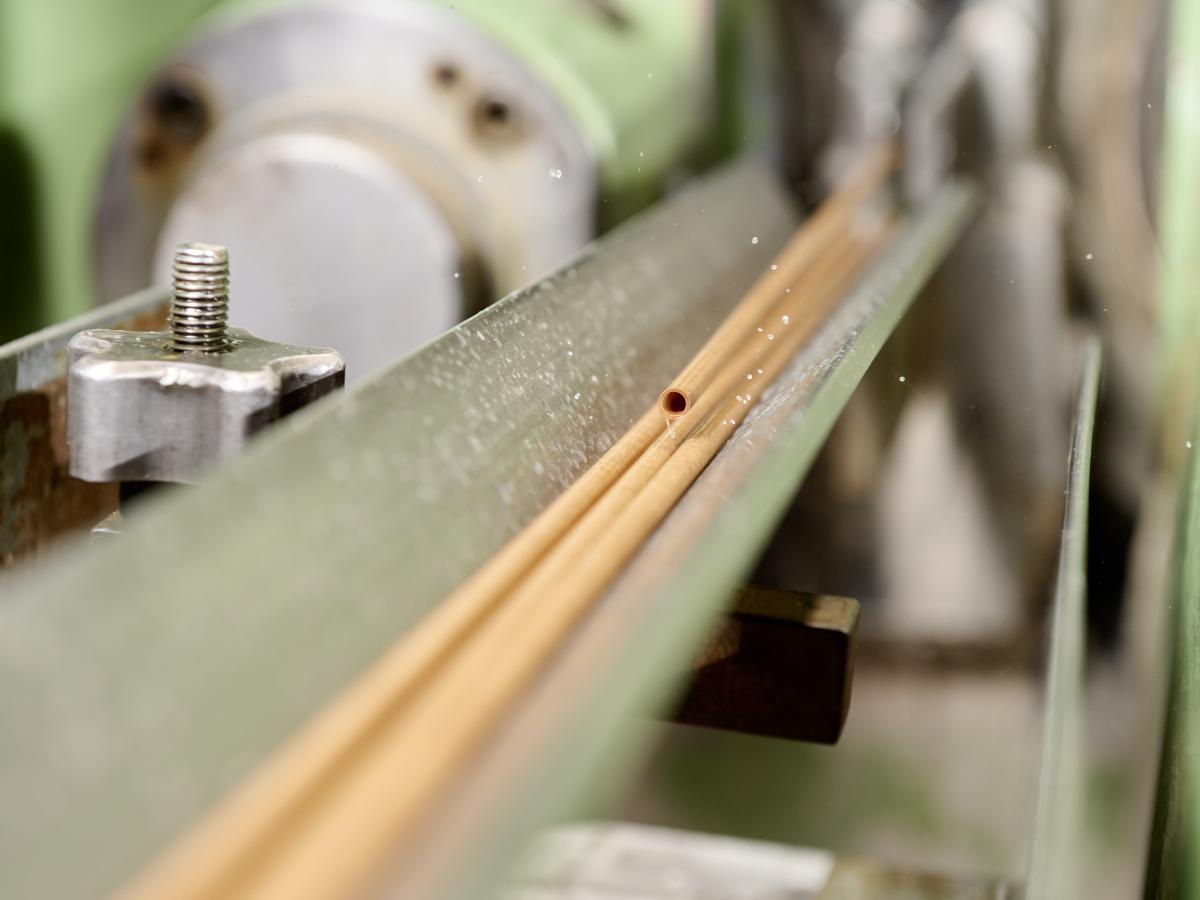

We produce bearing cages through both machining of our in-house tubes and high-performance moulding, enabling us to meet the demands of high-volume production and specialised applications alike. With full control over material production, machining, and moulding, our in-house capabilities ensure consistent quality, tight dimensional tolerances, and reliable execution of customer designs.

We also support customers who manufacture their own cages by supplying post-processed tubes in a wide range of sizes and specifications.

Benefits

- Low coefficient of friction

- High-speed capability

- Noise suppression

- Non-galling

- Ability to absorb / distribute lubricants

- Lightweight

- Good strength to weight ratio

- Excellent machining properties

- High performance and reliability

- Good impact resistance

- Mechanical and thermal stability

- Very good price-performance ratio

Key features

- Technologies: convolute winding, injection moulding

- Materials: fibre-reinforced phenolic resin with an extra fine, fine or medium woven cotton fabric, injection moulded advanced polymers

- Operating temperatures: > 270°C (dependent on material choice)

- Tube lengths: up to 1200 mm

- Outside diameter: 4.5 - 600 mm

- Inside diameter: >2.35 mm

Areas of application

- CNC machine tools

- compressors, pumps, gear boxes

- dental drills, surgical tools

- engines, landing gear systems

- home appliances

Exceeding standards with certified quality and precision inspection

Krempel stands for high quality that not only complies with, but often surpasses all common international standards. We are accredited to ISO 9001 as well as AS 9100 and are members of the ADS, Hellios- JOSCAR and SC21.

We have a full inspection capability including 3D Scanning, Coordinate Measuring Machine (CMM) and traditional testing processes.