Pregnit TP

THERMOPLASTICS WITH MAXIMUM MOULDABILITY

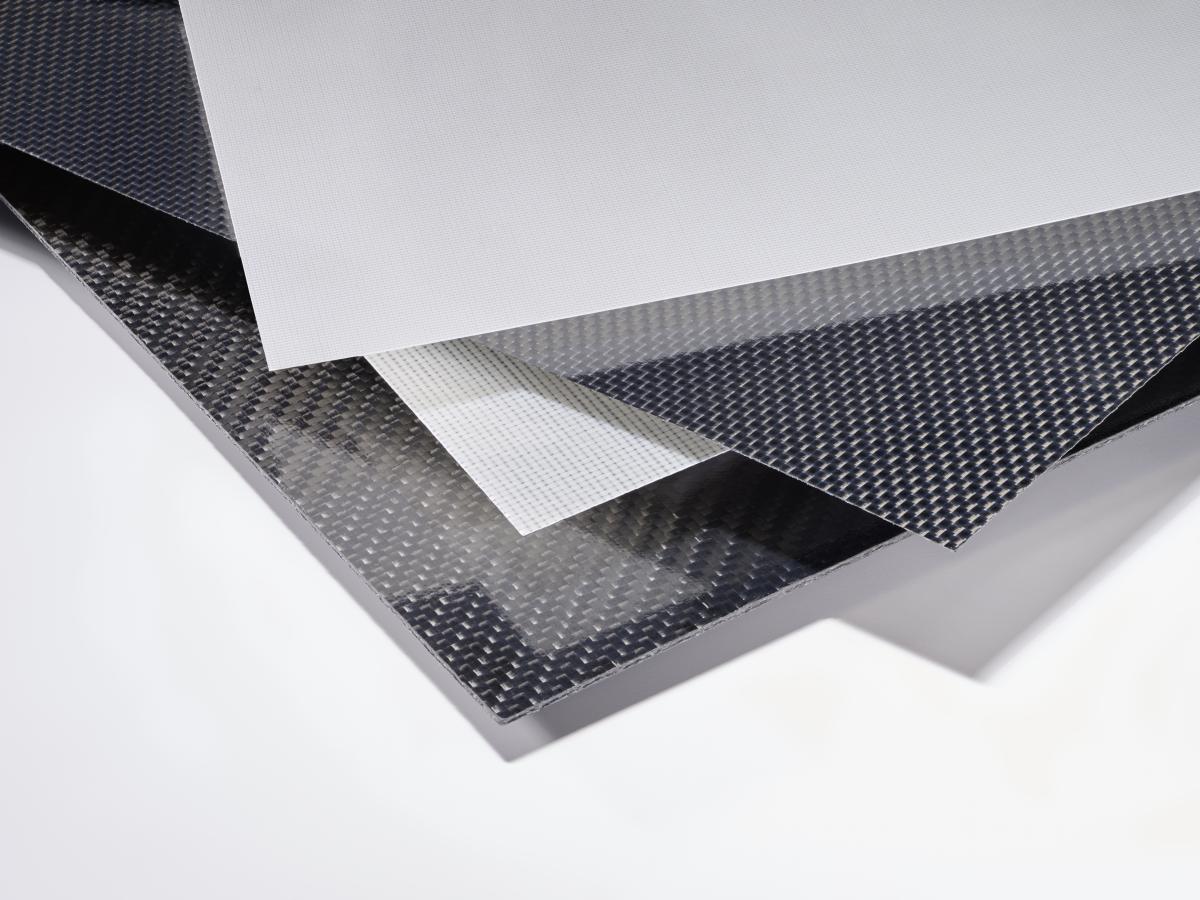

Krempel produces thermoplastic sheets and moulded parts under the name ‚PREGNIT TP‘. These so-called organosheets consist of several layers of glass or carbon fabric impregnated with various thermoplastic matrices. The number of layers can be flexibly adapted to customer-specific requirements in order to achieve the desired thickness with a high level of precision.

One outstanding feature of PREGNIT TP is its mouldability: The material can be reformed several times through heating above the softening point, as long as it is not thermally decomposed by overheating. This property makes the thermoplastics recyclable and means that they can be further processed to create high-quality fibre-reinforced components. Moulded parts can be produced in short cycle times by pressing or deep-drawing the sheet material, which makes them a particularly attractive substitute for sheet metal.

Optimal reinforcement through fibre fabric

The high mechanical strength of the organosheets is achieved by fibre reinforcement in the form of woven fabrics. Common fabric weaves are twill and plain weave. Plain weave fabric is evenly woven and has two identical sides, which offers a high level of durability and abrasion resistance. Twill weave has a diagonal pattern and is available in uniform and non-uniform weaves. It allows for a large number of variations, can be stiff or flexible depending on the thread density and offers better drapability than canvas fabric.

Thanks to the multi-layer structure with different reinforcement materials and directions, this weave allows for the flexible adaptation of sheet specifications. PREGNIT thermoplastics are characterised by low density, good abrasion resistance, high impact strength and high ductility even at low temperatures. They can be bonded to other thermoplastics without adhesive and are ideal as reinforcement in injection moulding processes.

Flexible standard portfolio

The standard portfolio includes thermoplastic matrices that can be combined with the following fabrics. In addition to standard fabrics such as twill and plain weave, a wide range of other fabric types are available, which can be selected according to customer requirements.

There is also the option to integrate layers with unidirectional fibre orientation and to use aramid fibres instead of glass or carbon fibres. This diversity offers customised solutions for specific requirements and applications.

Resin Matrix | Backing Material | Backing Material | Backing Material Grammage [g/m²] |

Acrylat (AC) | Glass filament fabric | Plain weave Plain weave | 203 290 |

Polypropylen (PP) | Glass filament fabric | Twill weave 2x2 Twill weave 2x2 | 200 280 |

Polyamid 6 (PA) | Carbon HT 3K | Plain weave | 200 |

Polyurethan (PU) | Carbon HT 3K | Twill weave 2x2 | 200 |

Diverse Thermoplastics

Organosheets are suitable for the partial reinforcement of injection-moulded and blow-moulded parts, as UV protection for outdoor applications and as a decorative protective surface.

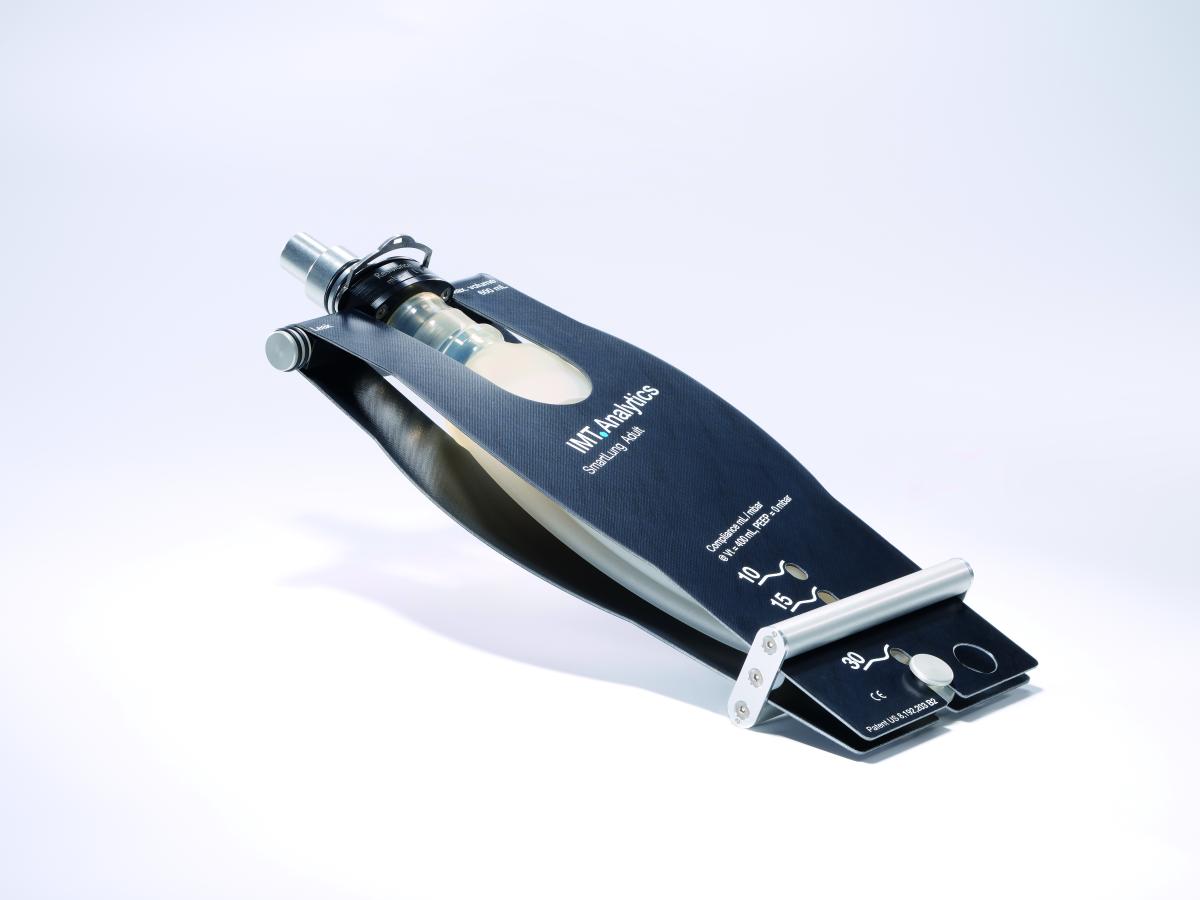

In the medical field, they are used in orthopaedic insoles for foot relief, sports insoles for comfort and performance, orthoses for joint stabilisation and prostheses to support rehabilitation. Another application is artificial lungs, which support or replace the natural lung function and ensure oxygen supply in patients with respiratory diseases.

Ankle protection systems for hands and feet offer protection during intensive activities and prevent injuries. In motorsport, they are integrated into protective clothing to protect the joints under high loads and increase safety.

Organosheets are used in the automotive sector due to their low weight and durability. They are often used in display surfaces and provide robust surfaces for screens and control elements in the dashboard area. They also serve as surface protection for coverings and as reinforcement material for the stabilisation of various vehicle parts. Pregnit thermoplastics are also used in the production of complex components and conveyor belts due to their flexibility and wear resistance.

Delivery forms

Sheet formats: | 1000 x 1500 mm |

| 1250 x 2500 mm | |

| 1500 x 3000 mm | |

| more on request | |

Tolerance: | -0 / +30 mm |

Precisely cut parts are also available; these are manufactured using CAD data and modern processes such as waterjet and laser cutting. These techniques allow for precise moulding according to digital designs: A high-pressure water jet is used for waterjet cutting and a focussed laser beam for laser cutting. Both processes deliver clean, precise edges and are ideal for detailed and intricate components.