Extended Service Life for Solar Modules

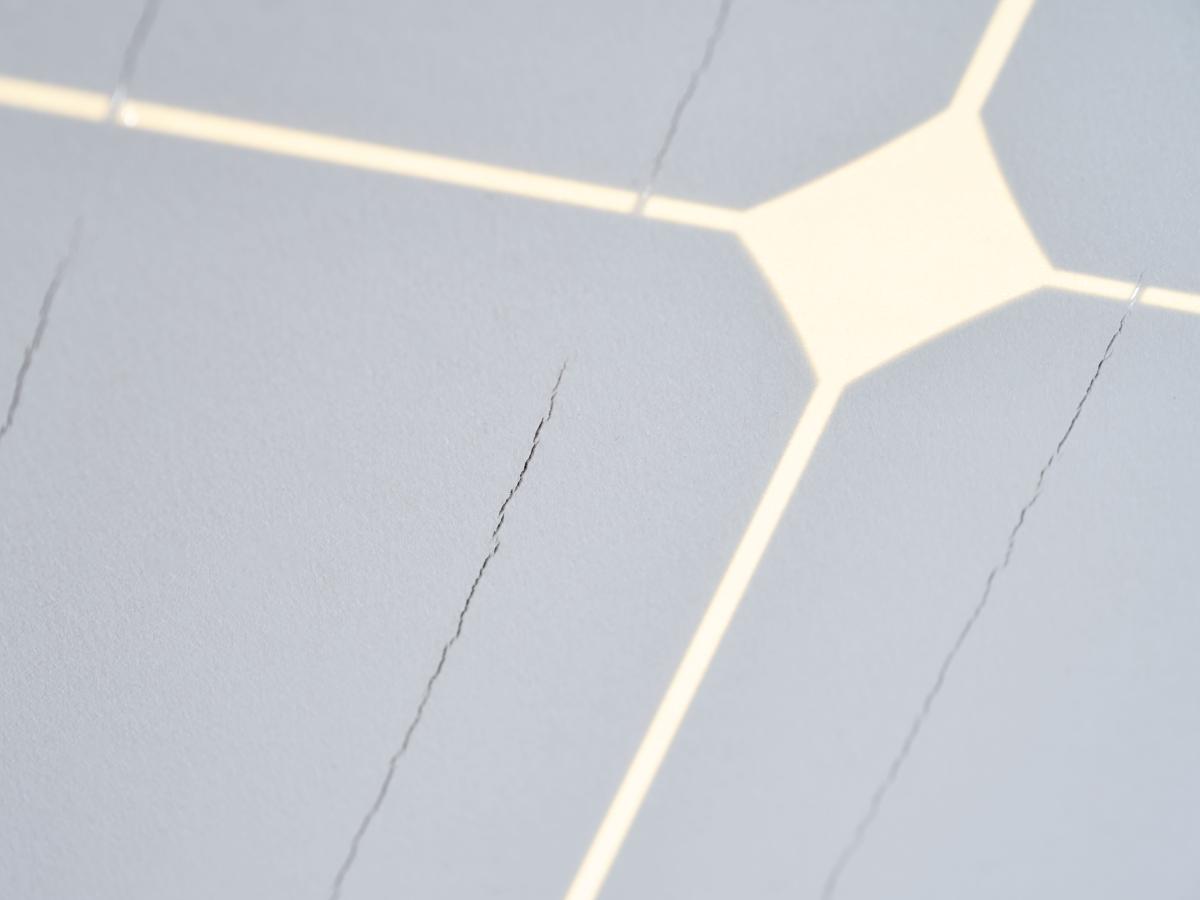

Damaged backsheet laminates are a major cause of premature aging and electrical risks in solar modules. If moisture penetrates due to impaired insulation performance, inverters may shut down and power production can come to a halt — resulting in significant yield losses. Modules with insufficient insulation resistance should be repaired without delay.

Our innovative repair solution, KremSol Repair, enables the effective refurbishment of damaged backsheet laminates, helping to significantly extend the service life of the modules. This repair approach is far more efficient and cost-effective than replacing damaged modules.

As a result, both material and energy requirements for manufacturing new modules are reduced, and the carbon footprint is significantly lowered. Longer utilization reduces waste, conserves valuable resources, and supports a sustainable circular economy — for more environmentally friendly and efficient solar energy.

Benefits at a Glance

- Extended Service Life: Preservation of module value through repair instead of replacement

- Safety: Reduced risk due to low insulation resistance

- Maximum Profitability: Prevent production downtime and yield losses

- Maintenance of Existing Infrastructure: No need to replace inverters or mounting systems

- Flexible & Customisable: Repair film available for all module sizes

- Proven Expertise: Over 30 years of expierence with PV module backsheet laminates

- Sustainable: Lower carbon footprint through reuse

- Environmentally Friendly: PFAS-free materials

Maximum Durability with Multi-Layer Design

KremSol Repair is made from a specially engineered combination of high-quality films. Each film serves a specific function to ensure optimal performance and long service life.

The films are permanently bonded using an adhesive developed by Krempel specifically for photovoltaic applications. The unique structure of KremSol Repair is composed of four high-performance materials:

- Outer PET film: UV- and hydrolysis-resistant

- Inner PET film: Insulation protection

- Pressure-sensitive PSA adhesive: For optimal adhesion

- Release liner: Protectiion for the PSA adhesive

The Smart Solution

KremSol Repair films with innovative film technology give operators of large solar parks the ability to repair damaged modules directly on site — without long waiting times. The simple, fast application makes the repair particularly efficient, helping to minimize downtime and significantly reduce yield losses for investors.

KremSol Repair also opens up exciting business opportunities for photovoltaic wholesalers as well as maintenance and service providers in this sector. With this practical solution, they can expand their service portfolio, enhance their market appeal, and secure attractive revenue prospects.

Easy and Fast Application

Damaged backsheet laminates are among the most common causes of premature aging and electrical risks in PV modules used in solar parks. If moisture penetrates the inside of the module, it can cause inverters to shut down and abruptly stop power production — leading to noticeable yield losses.

Instead of replacing an entire solar module at high cost, KremSol Repair offers a simple, fast, and cost-efficient alternative. This high-performance backsheet repair film reliably restores full functionality — without complex dismantling or long downtime.

Thoroughly clean the surface of the damaged PV module to remove all dust and grease. Use a suitable cleaning agent, such as isopropanol.

Peel back a section of the protective liner and fold it back. Align the repair film precisely and gently press it onto the backsheet.

Ensure that KremSol Repair is applied without bubbles. To do this, gradually remove the remaining protective liner using a spatula, pressing the adhesive surface evenly across the entire width.

Technical Details

| Properties | Unit | Typical value | Test method |

| Thickness | μm | 290±30 | EN 60674-2 |

| Adhesive thickness | μm | 50±5 | EN 60674-2 |

| Grammage | g/m² | 390±40 | EN 60674-2 |

| Dimensional stability | % | <1,2 | ASTM-1204 |

| Breakdown voltage | kV | >20 | EN 60674-2 |

| System voltage | V | 1000 (>0,150 mm) | IEC 61730:2016 |

| UV-Beständigkeit | h | based on ISO4892-3 |

Material Availability:

- Format width: 1020 mm or smaller

- Length: on request; punching possible

- Also available in rolls

Storage:

- Store in a dry environment at a room temperature of +25°C +/- 5°C and a relative humidity of 50% +/- 5%

Download

KremSol Repair

Quick Solar Panel Repairs