Fire protection redefined

Composites have become indispensable in modern mobility, enabling many innovations in the first place. In aircraft, trains, or electric vehicles, one factor is just as important as low weight: safety. In the event of a fire, every second can be crucial in saving lives.

Materials used in the rail, aerospace, and automotive industries must therefore meet strict requirements for flammability, smoke emission, and toxicity – in short: Fire-Smoke-Tox (FST).

Our latest composite innovation, the epoxy-resin-based prepreg system KremGuard, redefines the standards for low flame propagation, low smoke development and low toxicity.

Benefits at a glance

- Maximum safety: Meets the highest Fire-Smoke-Tox requirements (minimal flammability, heat release, and smoke emission)

- Mechanical strength: High load-bearing capacity for demanding applications

- Health-conscious: Free from phenol, formaldehyde, and halogens

- Versatile in use: Ideal base for structural components and honeycomb sandwiches

- Premium surface quality: Homogeneous and pore-free – easy to paint

- Durable & stable: Enhanced durability and shelf life compared to conventional phenolic systems

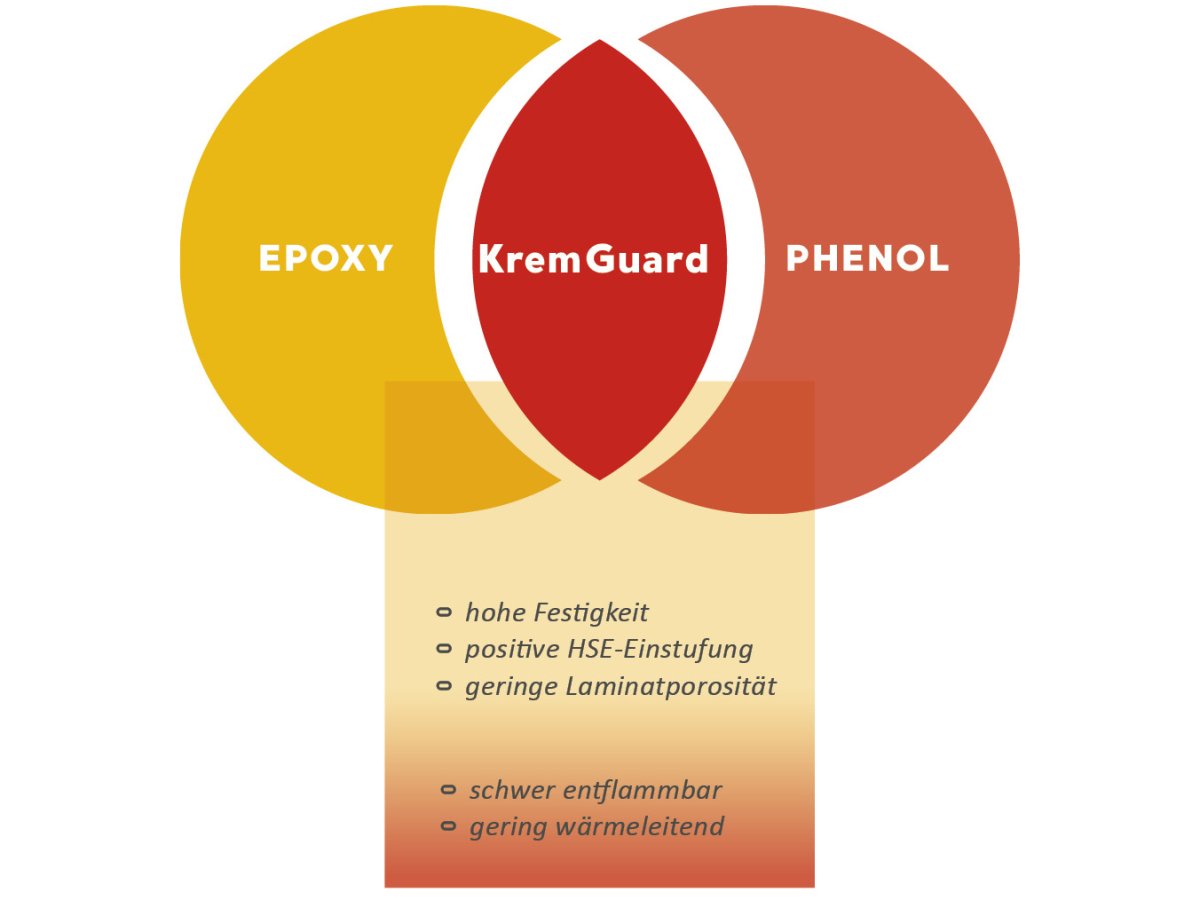

Epoxy and phenolic technology – innovatively blended

In developing KremGuard, we have combined the best properties of epoxy and phenolic. The result: outstanding fire and heat protection. Even in complex structures, KremGuard is non-flammable, conducts only minimal heat, and produces hardly any smoke or toxic gases – all without harmful phenols, formaldehyde, or halogens.

In addition, KremGuard offers high mechanical strength, is easy to process even with demanding geometries, and features a homogeneous, pore-free surface that is easy to paint.

This makes KremGuard ideal for interior, exterior, structural, and sandwich components – and it surpasses existing phenolic systems in durability and shelf life at room temperature.

Highest safety standards

KremGuard meets all relevant regulations and standards for use in aircraft and trains – including FAR 25, AIMS, AITM, and EN 45545 up to the highest classification, HL3.

In addition, KremGuard has been successfully classified according to UL-94 V0 – one of the most important test methods for assessing the flammability of plastics. The UL Torch & Grid Test also confirms its outstanding fire protection performance.

The result: KremGuard meets the stringent safety requirements in a wide range of applications – from rail vehicle interiors to automotive components and battery housings.

From prepreg to finished component

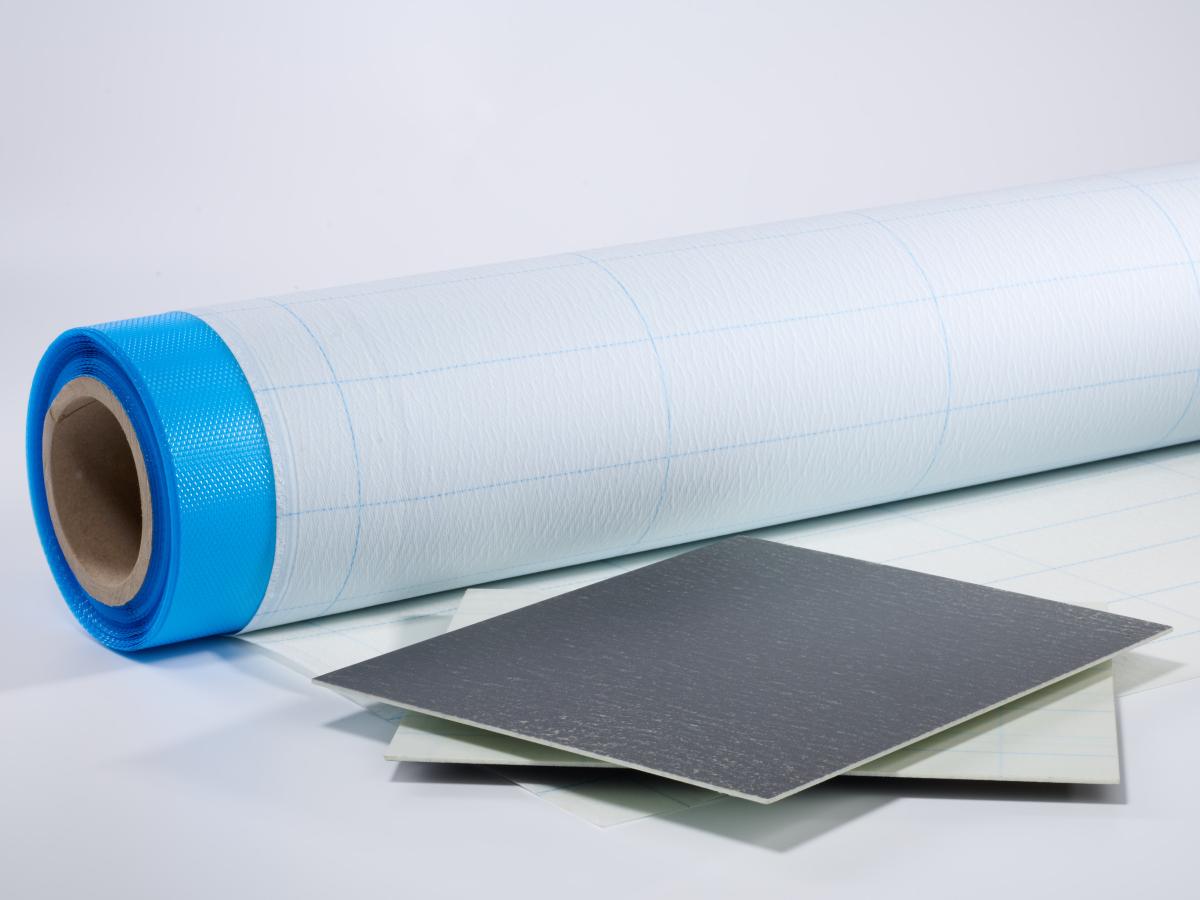

- Epoxy-based Prepregs

High-performance prepregs with excellent fire protection (FST-compliant) for demanding composite applications - Rigid Laminates / Laminate Sheets

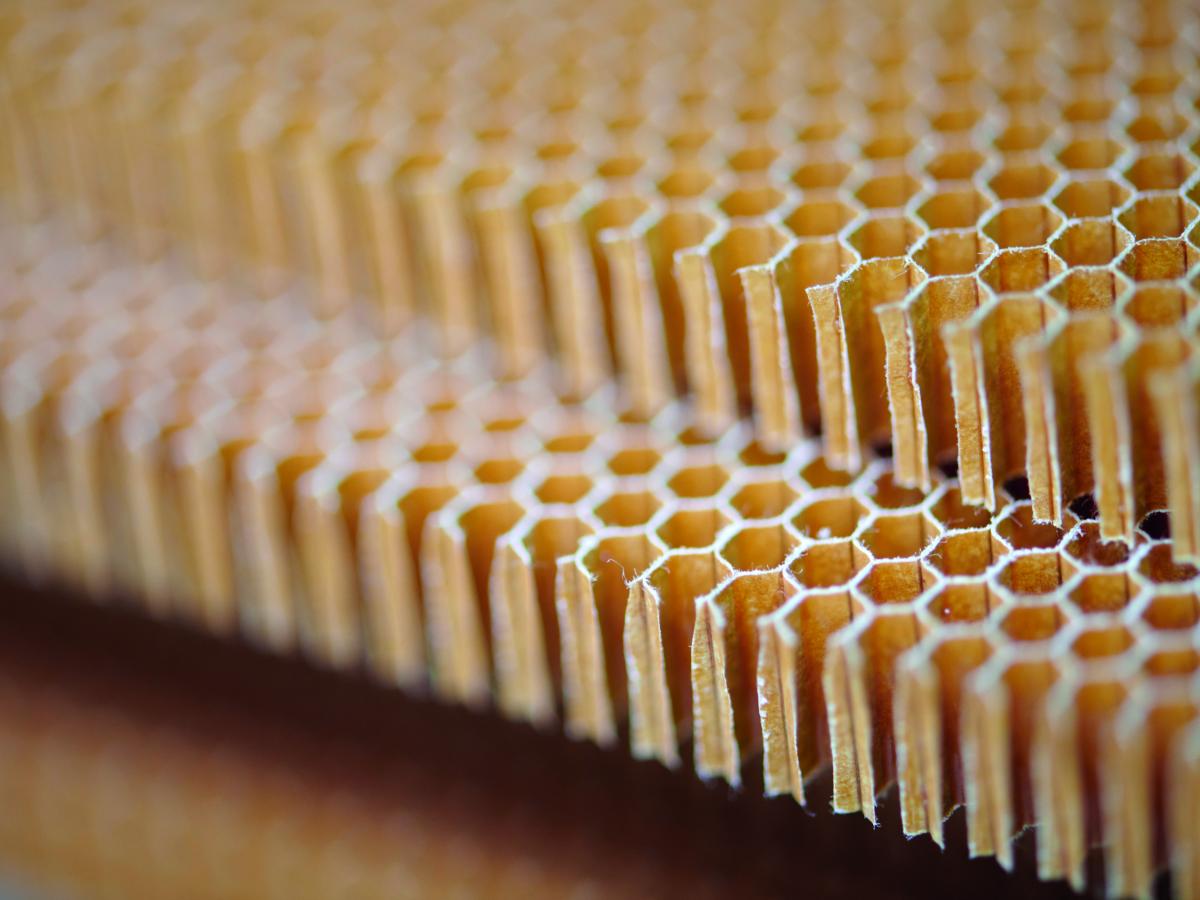

Layer-pressed materials with a pore-free surface – ideal for structural components with high mechanical performance - Sandwich Panels and Components (Honeycomb Structure)

Lightweight, high-strength sandwich solutions with honeycomb core, perfect for interior, exterior, and structural applications - Finished Components

Pre-manufactured components based on the KremGuard system – ready for direct use in aerospace, rail, and automotive sectors

Exceptional in any environment

KremGuard is ideal for use in vehicle interiors – for example, in trains or aircraft. The combination of low weight, high dimensional stability, and low flammability ensures maximum safety while maintaining full design freedom.

Its pore-free surface is easy to paint and seamlessly integrates into modern interior concepts. In this way, KremGuard meets the highest fire safety standards without compromising on creative flexibility.

In exterior applications, KremGuard impresses with its weather resistance, high mechanical strength, and non-combustible properties – all without halogen-based flame retardants.

The material is perfectly suited for exterior cladding, modular housings, or functional panels in rail and vehicle construction. KremGuard not only offers structural strength but also ensures safety in the event of a fire.

For load-bearing or reinforcing structural components, KremGuard delivers an ideal combination of mechanical strength, low thermal conductivity, and excellent flame resistance.

The material is particularly well-suited for sandwich constructions with honeycomb cores and can be processed efficiently – even with complex geometries. KremGuard clearly outperforms conventional phenolic systems in terms of durability, shelf life, and processing quality.

Download

KremGuard - Fire and Flame Safety

Epoxy prepreg system for maximum fire protection