The new product is based on proven, high-performance materials and offers the same high quality, durability and safety as those used in new PV modules. Krempel is thus providing an important impetus towards a sustainable circular economy in the solar industry.

Resource-saving, efficient and environmentally friendly

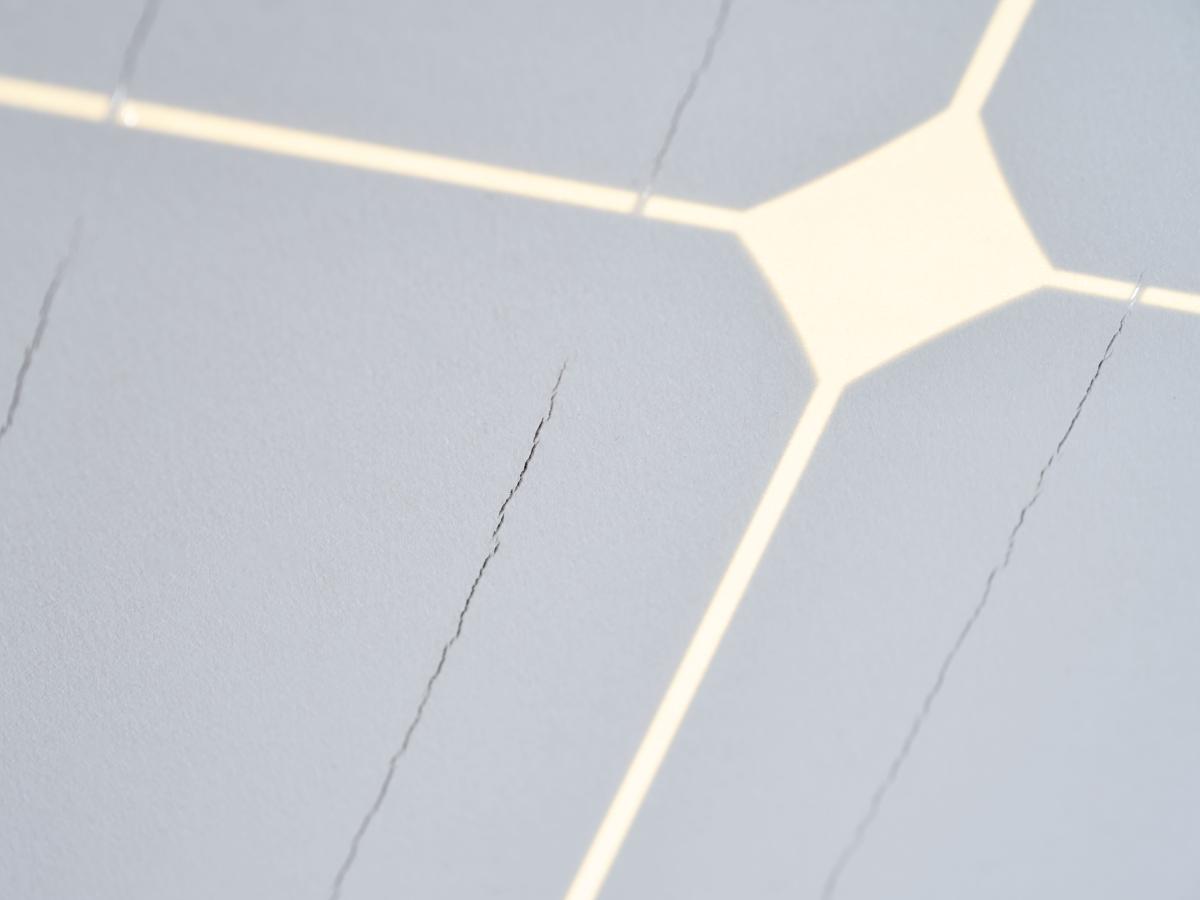

KremSol® Repair enables damaged module backsheets to be repaired with pinpoint accuracy without having to replace the entire module. This not only saves time and money, but also reduces CO₂ emissions – a clear advantage in terms of resource conservation and environmental awareness. The repair film impresses with its outstanding weather resistance, excellent insulation properties and high UV and ageing resistance. It can be applied reliably and ensures long-term restoration of the protective function.

Flexible application for various processes

The material is available in the form of pre-cut sheets or rolls, allowing it to be flexibly integrated into existing repair processes. The high accuracy of fit, easy handling and strong adhesion enable quick, safe and simple repairs directly on site. KremSol® Repair thus offers a genuine alternative to replacing damaged solar modules and actively contributes to extending the service life of existing PV systems.

A clear contribution to sustainability for solar park operators

With this product, Krempel is responding to the growing importance of sustainability and service in the photovoltaic industry. The repair films are particularly suitable for operators, investors and managers of solar parks, as well as for solar dealers and service providers in the field of maintenance and repair.

Further information and technical details can be found here