Flexible strength for demanding applications

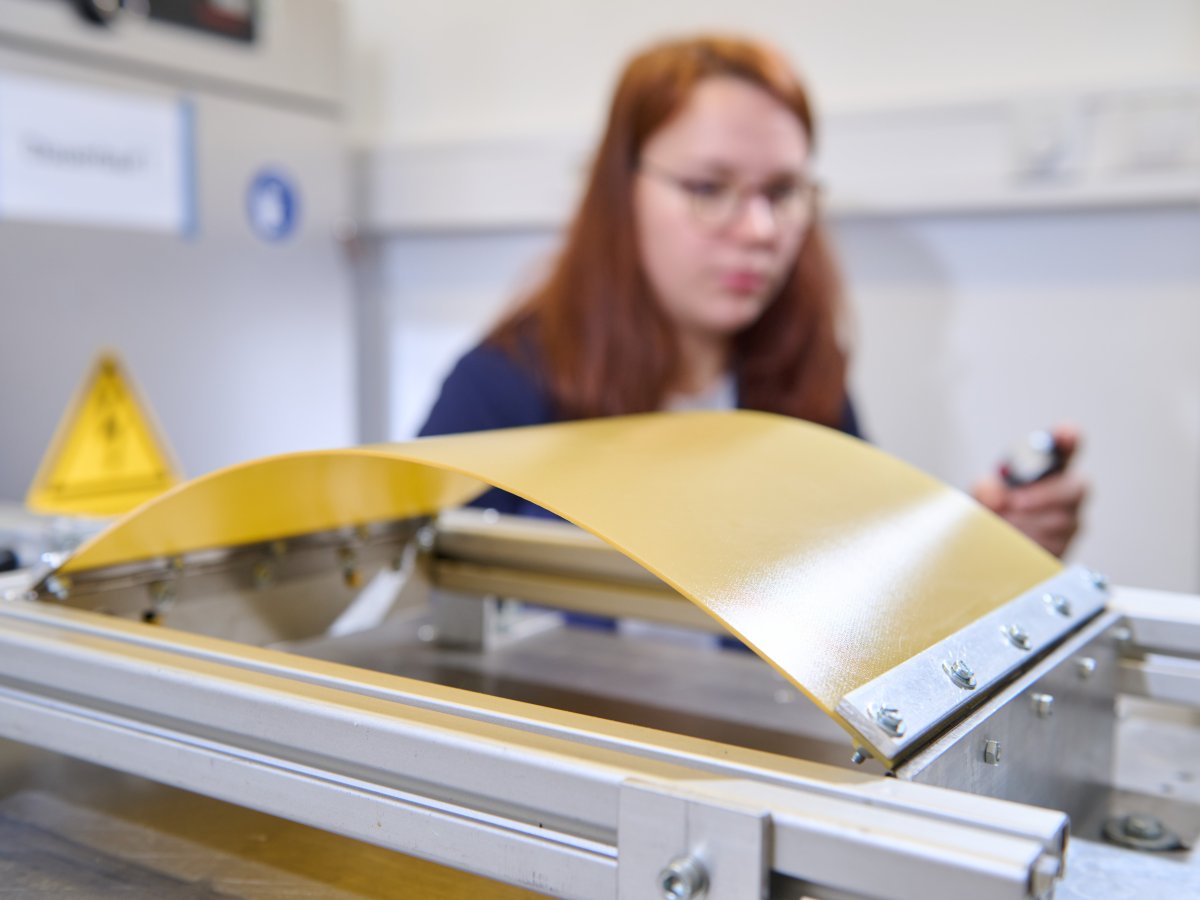

Our innovative phenolic resin system combines high mechanical performance with exceptional dynamic fatigue resistance.

It can be processed safely, adapts flexibly even to complex shapes and meets the highest requirements for strength, dynamics and fire protection.

Krempel is one of the innovation leaders in this field, modifying and processing resin systems into performance-optimised prepregs, laminates and components that take modern composite solutions to a new level.

Advantages at a glance

- Mechanical performance: high mechanical and dynamic performance – up to 1.5 million alternating load cycles

- Processing properties: excellent flexibility and drapability

- Emissions and environmental compatibility: very low formaldehyde content (<0.1%) and low emissions

- Compliance with standards and approvals: certified according to EN 45545-2 HL3 R1 / R7

- Areas of application: developed and optimised for maximum alternating load resistance in demanding railway and aviation applications (e.g. gangways in trains)

Phenolic resin technology at the highest level for composite materials

With a specially flexibilised phenolic resin prepreg system, Krempel creates the basis for high-performance prepregs and complex composite components. Our solutions are based on high-performance thermosetting phenolic resin systems and a wide range of modern reinforcement fibres, including glass, carbon, aramid, basalt and hybrid fibres. The strength and drapability of the prepregs can be controlled by selecting the weave and grammage.

In addition to lacquered composite surfaces in accordance with EN 45545-2 HL3 R1/R7/R17, we also offer the option of applying decorative films – either during the pressing process or subsequently using PSA.

Individually selectable surface qualities – press-smooth, textured or sanded – offer maximum flexibility and facilitate further processing by the customer.